When it comes to MIG welders, the Hobart Handler 210 is a well-known and respected name in the industry. This welding machine is designed for both DIY and professional welders. Who need a reliable and powerful tool to handle their welding tasks. This review will examine the features, benefits, and drawbacks of the Hobart Handler 210 to help determine if it’s the right choice for your needs. Let’s take a look on Hobart Handler 210 Review.

- Hobart Handler 210 Specifications

- Hobart Handler 210 Review

- Versatile

- Duty cycle

- Spool size

- 7 Voltage Settings

- Heat Settings

- Infinite Wire Feed Speed Control

- Durability

- Versatility

- Dual-Groove Quick-Change Drive Roll System

- Built-in Thermal Overload Protection

- Industrial Cast Aluminum Drive System

- Large Welding Capacity

- Why People Prefer This Product

- Features of Hobart Handler 210

- Additional Features

- Warranty & Service

- Pros and Cons

- How to assemble Hobart handler 210 MVP MIG welder

- Hobart handler 210 replacement parts

- Hobart Handler 210 MVP parts diagram

- Hobart 210 MVP problems

- FAQ’s of Hobart Handler 210 Review

- Final Thoughts on Hobart Handler 210 Review

Hobart Handler 210 Specifications

| Welding Processes: | MIG (GMAW), Flux-cored (FCAW) |

| Input Voltage: | 115/230V, 60Hz |

| Amperage Range: | 25-210A |

| Duty Cycle: | 20% @ 90A, 230V – 30% @ 150A |

| Wire Feed Speed Range: | 40-680 IPM |

| Weld Thickness Range: | 24 ga. – 3/8 in. mild steel |

| Spool Size: | 4 in. or 8 in. |

| Dimensions: | 12.375 in. H x 10.625 in. W x 19.5 in. D |

| Weight: | 79 lbs. |

| Voltage: | 115V |

Hobart Handler 210 Review

The Hobart Handler 210 is a MIG welding machine with a 230-volt input power and a 25 to 210 amps welding range. It can weld stainless steel and aluminum materials up to 3/8 inch thick. The welding machine has a built-in gas valve, 10-foot MIG gun, dual gauge regulator, gas hose, and power cord. The Hobart Handler 210 is also compatible with spool guns for welding aluminum.

Here are in-depth review of hobart handler 210

Versatile

The Hobart 500553 Handler 210 MVP MIG Welder is a versatile welding machine offering MIG and Flux-cored welding capabilities. It has an input voltage of 115/230V and an amperage range of 25-210A, making it suitable for a wide range of welding applications.

Duty cycle

The duty cycle for this machine is 115V – 20% @ 90A and 230V – 30% @ 150A, which means it can operate continuously without overheating within those time and amperage limits. The wire feed speed range is 40-680 IPM, and it can weld mild steel with a thickness range of 24 ga. – 3/8 in.

Spool size

The spool size for this machine is either 4 in. or 8 in., and it has a compact design, measuring 12.375 in. H x 10.625 in. W x 19.5 in. D. It weighs 79 lbs., making it relatively portable and easy to transport to job sites.

7 Voltage Settings

The Hobart Handler 210 has seven voltage settings that allow you to adjust the power output to suit the thickness of the material you’re welding. The voltage control knob is easy to use, and each setting is marked on the machine. This feature is particularly useful when welding thicker materials, as it helps to produce a stronger, more consistent weld.

Heat Settings

The Hobart Handler 210 MVP MIG Welder offers adjustable heat settings that allow you to customize the welding parameters based on the specific application and material you are working with. The machine has a 7-tap voltage control selector that allows you to fine-tune the voltage output to match the thickness and type of metal you are welding.

Infinite Wire Feed Speed Control

The Hobart Handler 210’s infinite wire feed speed control allows you to fine-tune the welding speed for a more precise weld. The wire feed speed can be adjusted using the dial on the front of the machine, and the display shows the current setting. This feature is especially useful when welding thin materials, as it allows you to control the speed of the wire feed for a smoother, more controlled weld.

Durability

The Hobart Handler 210 MVP MIG Welder has high-quality components and sturdy construction, making it a durable and reliable machine for industrial and workshop use. Its all-metal wire drive system provides consistent and reliable wire feeding, and is easy to maintain and repair.

The cast aluminum drive system reduces the risk of wire tangling and birdnesting, while providing smooth and consistent wire feeding. The built-in thermal overload protection system prevents damage to the machine’s internal components in case of overheating, ensuring reliable performance over time. Overall, the Hobart Handler 210 MVP MIG Welder is a smart choice for anyone needing a dependable, long-lasting MIG welding solution.

Versatility

The Hobart Handler 210 MVP MIG Welder is a highly versatile machine that can easily handle a wide variety of welding tasks. It has an adjustable voltage control allows for fine-tuning of the arc, making it suitable for welding various materials, including aluminum, stainless steel, and mild steel.

Dual-Groove Quick-Change Drive Roll System

The Hobart Handler 210’s dual-groove quick-change drive roll system is designed to make switching between different wire sizes easy. The drive roll system is made of high-quality materials, and the dual-groove design ensures that the wire is fed smoothly and evenly. The quick-change feature makes it easy to change the drive rolls, saving you time and effort when switching between different welding projects.

Also Read: Century FC 90 Welder Review

Built-in Thermal Overload Protection

The Hobart Handler 210 is equipped with built-in thermal overload protection, which shuts off the power to the machine if it gets too hot. This feature helps to protect the internal components of the machine from damage, and it can also help to prevent accidents. The thermal overload protection is an important safety feature that ensures the Hobart Handler 210 is a reliable and safe tool.

Industrial Cast Aluminum Drive System

The Hobart Handler 210’s industrial cast aluminum drive system is designed to ensure that the wire feed is smooth and consistent. The drive system is made of high-quality materials and designed to last. The industrial cast aluminum drive system is also easy to clean, which can help extend the machine’s life.

Large Welding Capacity

The Hobart Handler 210 can weld materials up to 3/8 inch thick, which makes it suitable for a wide range of welding tasks. The machine is powerful enough to handle thick materials but versatile enough to weld thin materials precisely. The large welding capacity of the Hobart Handler 210 makes it a reliable and versatile tool for DIY and professional welders.

Why People Prefer This Product

One of the reasons why people prefer the Hobart Handler 210 is its reliability and ease of use. This welding machine is built to last and can handle many welding tasks. The Hobart Handler 210 also has a smooth arc that produces high-quality welds with minimal spatter. Additionally, the welding machine is easy to set up and use, even for beginners.

Features of Hobart Handler 210

- 7 voltage settings for precise welding control

- Infinite wire feed speed control

- Built-in thermal overload protection

- Aluminum drive system for durability

- Quick select drive roll for easy setup

- Fan-on-demand cooling system for longer life

Additional Features

- Compatible with spool guns for welding aluminum

- 10-foot MIG gun and power cord included

- Dual gauge regulator and gas hose included

- Built-in gas valve for convenience

Warranty & Service

The Hobart Handler 210 has a 5/3/1 warranty covering the transformer, drive system, and parts and labor. Hobart also provides technical support and repair services for their welding machines.

Pros and Cons

Pros:

- Reliable and durable

- Produces high-quality welds

- Easy to set up and use

- Compatible with spool guns for welding aluminum

Cons:

- Heavy and bulky

- Some users have reported issues with the wire feed system.

How to assemble Hobart handler 210 MVP MIG welder

Assembling the Hobart Handler 210 MVP MIG Welder is a relatively straightforward process that can be completed by following these steps:

- Unpack the Welder: Remove the welder from its packaging and ensure all components are present.

- Attach the Handle: Attach the handle to the top of the welder using the included bolts and nuts.

- Install the Gas Regulator: Screw the gas regulator onto the valve on the back of the welder and tighten it using a wrench.

- Install the Wire Spool: Remove the protective cover from the wire spool holder and slide the wire spool onto the holder. Ensure the wire spool is correctly positioned and aligned with the drive system.

- Install the Drive Roll: Open the wire drive compartment on the side of the welder and install the drive roll onto the drive motor. Ensure that the drive roll is correctly positioned for the wire size.

- Install the Contact Tip: Remove the nozzle from the welding gun and install the contact tip. Ensure that the contact tip is tightened securely.

- Connect the Ground Clamp: Connect the ground clamp to the ground stud on the front of the welder and tighten it using a wrench.

- Connect the MIG Gun: Connect the MIG gun to the welder using the included cable and tighten the connector using pliers.

- Plug in the Welder: Plug the welder into a suitable power outlet and turn it on.

- Adjust the Welder Settings: Adjust the welder settings for the welding application, including wire speed and voltage.

Hobart handler 210 replacement parts

- H100S4-10 MIG gun

- Built-in gas solenoid valve

- Dual-gauge regulator with gas hose

- 10 ft (3 m) work cable with clamp

- Power cord with MVP adapter plugs for 120V and 240V

- 10 ft (3 m) primary input cable with plug

- Spare .030″ contact tips

- Sample spool of .030″ flux-cored wire

- Material thickness gauge

- Owner’s manual and setup DVD

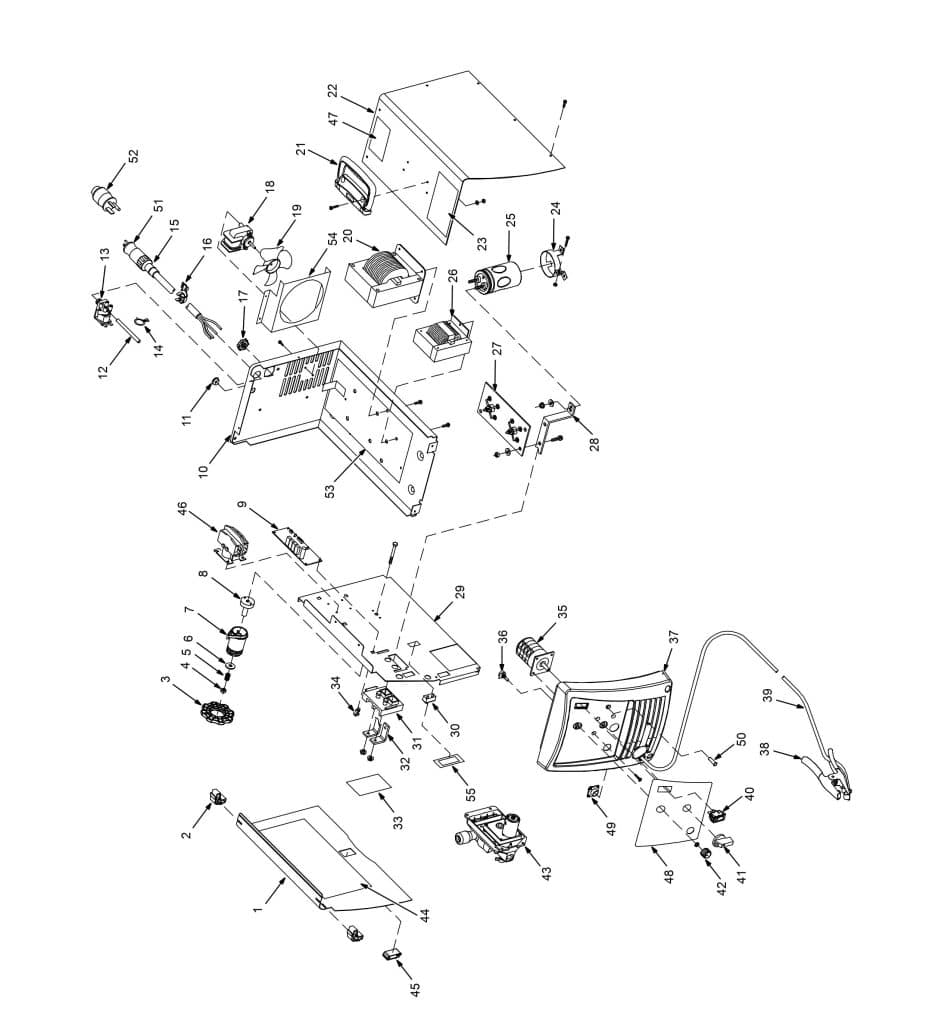

Hobart Handler 210 MVP parts diagram

Hobart 210 MVP problems

While the Hobart Handler 210 MVP MIG Welder is a reliable and high-quality machine, it may encounter issues over time like any welding equipment. Here are some common problems that users of this machine have reported, along with potential solutions:

Wire Feeding Issues

Sometimes the wire may not feed properly, causing issues with the weld quality. This could be due to issues with the wire spool or feeder. Solutions to this problem include ensuring the wire spool is properly loaded, checking for any blockages in the wire feeder, and ensuring the wire drive roll tension is properly set.

You may also Like the following:

Poor Weld Quality

If the weld quality is poor or the arc is inconsistent, it could be due to incorrect settings or problems with the wire, gas flow, or ground. Try adjusting the voltage, wire feed speed, and gas flow to the recommended settings for your project. Also, check the condition of the wire and ground, and replace them if necessary.

Overheating

If the machine overheats, it may shut off or stop working altogether. This could be due to poor ventilation or using the machine beyond its duty cycle. Ensure the machine is well-ventilated and not placed near other equipment that could generate heat. Also, be sure to follow the recommended duty cycle for the machine.

Burnt Tips

If the welding tips become burnt or damaged, it could affect the quality of the weld. This could be due to improper settings or dirty or worn tips. Adjust the voltage and wire feed speed, and replace the tips if dirty or worn.

Wire Tangling

If the wire becomes tangled or knotted, it could affect the quality of the weld and damage the machine. This could be due to issues with the wire spool or the wire drive system. Check the wire spool and drive system for any blockages or issues, and ensure the wire spool is properly loaded.

FAQ’s of Hobart Handler 210 Review

What’s the maximum thickness the Hobart Handler 210 can weld?

The Hobart Handler 210 can weld materials up to 3/8 inch thick.

Is the Hobart Handler 210 compatible with spool guns for welding aluminum?

The Hobart Handler 210 is compatible with spool guns for welding aluminum.

Does the Hobart Handler 210 come with a warranty?

Yes, the Hobart Handler 210 has a 5/3/1 warranty covering the transformer, drive system, parts, and labor.

Is the Hobart Handler 210 easy to set up and use?

Yes, the Hobart Handler 210 is designed for ease of use, even for beginners.

Can the Hobart Handler 210 be used for DIY and professional welding tasks?

The Hobart Handler 210 is suitable for DIY and professional welding tasks.

Final Thoughts on Hobart Handler 210 Review

The Hobart Handler 210 is a reliable and robust MIG welder suitable for DIY and professional welding tasks. It’s built to last, produces high-quality welds, and is easy to set up and use. While it may be heavy and bulky, the welding machine’s performance and durability make it a top choice for welders who need a tool that can handle a wide range of welding tasks. Overall, we highly recommend the Hobart Handler 210 as a solid investment for any welder.