To bleed pressure welding requires opening the bleed valve until the air is completely removed from the system. To bleed pressure welding, follow these steps.

Properly bleeding pressure welding is essential to ensure safety and optimal performance. If air is trapped inside the lines, it can cause weak welds and even dangerous blowouts. Bleeding allows air to escape from the system, ensuring that the welder can perform at maximum efficiency.

The process is straightforward and can be done quickly by anyone with basic welding knowledge. In this article, we’ll guide you through all of the steps necessary to bleed pressure welding safely and effectively. By following these guidelines, you can rest assured that your welding system will perform at its best every time.

- Understanding Pressure Welding

- Importance Of Proper Bleeding In Pressure Welding

- Step-By-Step Guide To Bleeding Properly

- Tips For Successful Pressure Welding

- Why Do You Need To Bleed It?

- When Should You Bleed Pressure Welding?

- How Do You Bleed Pressure Welding?

- What Are The Benefits Of Bleeding Pressure Welding?

- What Are Some Common Mistakes

- Final Thoughts on Bleed Pressure Welding

Understanding Pressure Welding

Pressure welding is a type of welding that uses both heat and pressure to join two pieces of metal together. This type of welding is often used in industrial applications and can provide a stronger and more durable weld than other types of welding techniques.

One of the benefits of pressure welding is that it can be used to join dissimilar materials together, which is not possible with other types of welding. There are different types of pressure welding techniques, such as resistance welding, forging, and friction welding.

Each technique has its own advantages and disadvantages depending on the application. Understanding pressure welding and its benefits can help you decide if it is the right type of welding for your project.

Importance Of Proper Bleeding In Pressure Welding

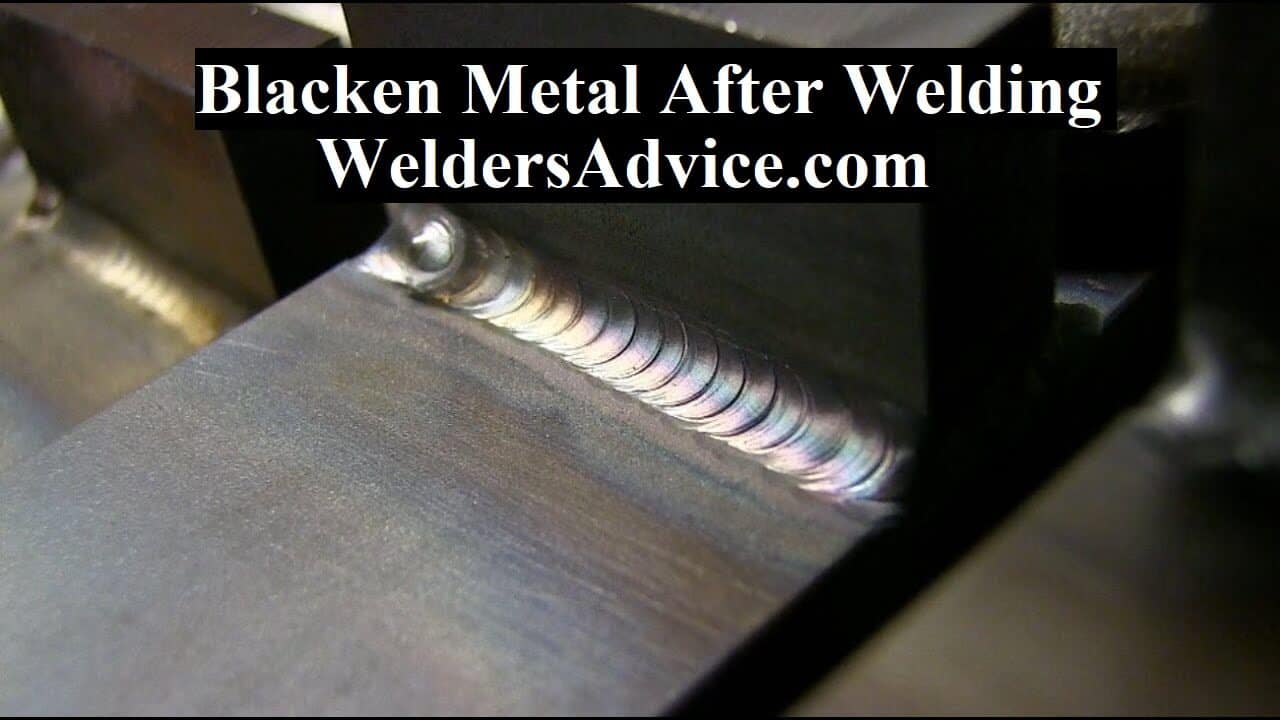

Bleeding is a process that releases air pockets from a pressure welding system. Proper bleeding is essential to maintain a safe and efficient welding process. Bleeding removes unwanted bubbles from the system, ensuring the welding fluid reaches the target points.

This improves the overall quality of the final product. Failure to bleed can lead to a variety of consequences, including damaged equipment, shoddy workmanship, and most concerning, risks to human life. Without proper bleeding, air pockets can build up in pipes and tanks, increasing the pressure and risking an explosion.

Therefore, a conscientious welder should always bleed the system carefully before starting the welding process.

Step-By-Step Guide To Bleeding Properly

Bleeding pressure welding equipment ensures that the system works efficiently with no air pockets. Firstly, it’s essential to prepare the equipment for bleeding. Secondly, identify the bleeding points within the system. Thirdly, open the valves to let out the air pockets.

Fourthly, remove any trapped air pockets within the system. Fifthly, check the pressure gauge and release any excess pressure that may have built up. Lastly, close the bleed valves once the bleeding process is complete. Bleeding pressure welding equipment is an essential part of maintaining the equipment’s longevity and ensuring it runs smoothly.

Following these steps carefully will preserve its functionality and improve productivity.

Tips For Successful Pressure Welding

Pressure welding involves an intricate process that demands specific preparation and execution. To ensure success, you must follow a set of best practices. First, avoid common mistakes such as inadequate preparation or lack of attention to necessary details. Second, make sure to select the appropriate welding technique and use clean and well-maintained equipment.

Further, utilize proper safety protocols and protective gear throughout the process. Additionally, to avoid heat distortion or warping of the material, use minimal heat input and a consistent pace. Lastly, take note of the specificities of the project, such as the type of material being used.

By following these tips, you can ensure effective and successful pressure welding, while minimizing issues and ensuring a durable and functional final product.

Why Do You Need To Bleed It?

Bleeding pressure welding removes trapped air, preventing contamination and ensuring a strong, smooth weld.

When Should You Bleed Pressure Welding?

You should bleed pressure welding whenever you are about to start a new weld job or whenever you detect contamination or air in the lines. Bleeding before welding ensures a strong, smooth, and reliable weld.

How Do You Bleed Pressure Welding?

To bleed pressure welding, start by closing valves and loosening fittings to release built-up pressure. Then, slowly open the valves to release air and ensure a smooth and steady flow of gas or liquid through the welding lines.

What Are The Benefits Of Bleeding Pressure Welding?

Bleeding pressure welding helps ensure the quality and reliability of the weld by eliminating trapped air and preventing contamination. It also helps extend the life of your welding equipment by preventing strain and damage to the machinery.

What Are Some Common Mistakes

Common mistakes include forgetting to close valves before loosening fittings, bleeding too quickly, and failing to check for contamination before starting the weld. Taking the time to bleed pressure welding correctly can save time, money, and frustration down the line.

Final Thoughts on Bleed Pressure Welding

After learning the process of pressure welding and bleeding to release any trapped air, you can proceed with confidence. The importance of bleeding can’t be overstated as it helps to prevent any issues that could arise during welding operations. By following the steps outlined in this guide, you’ll be able to avoid any potential problems that may result from improperly prepared equipment.

Additionally, a clear understanding of how to bleed pressure welding equipment will save you time and money in the long run. It’s crucial to remember that bleeding needs to be done even if the equipment appears to be working fine. It’s always better to err on the side of caution, and bleeding is one of the best preventative measures.

We hope that this guide has provided you with valuable information and helped boost your confidence in operating pressure welding equipment.