To Perfectly Blend welds, first, grind down the surface of the metal until it is smooth. From there, use a grinder or sander to blend the weld with the surrounding metal.

Blending welds is an essential process when it comes to welding. It is where you grind down the surface of the metal until it’s smooth and then use a grinder or sander to blend the weld with the surrounding metal.

Welding is the process of using heat or pressure to join two pieces of metal together and blending welds ensures that the joined surface is smooth and has the same surface finish as the surrounding metal. This is critical for aesthetic purposes, as well as for ensuring structural integrity. In this article, we will discuss the steps involved in blending welds, the equipment required, the techniques involved, and some tips and tricks to get the best results.

- Understanding The Importance Of Blending Welds For A Perfect Finish

- Essential Tools And Materials For Blending Welds

- Step-By-Step Guide To Blending Welds Like A Pro

- Advanced Techniques For Perfectly Blending Welds

- What Are The Benefits Of Blending Welds?

- What Tools Are Needed For Blending Welds?

- What Techniques Can Be Used For Blending Welds?

- Can Beginners Learn How To Blend Welds?

- Final Thoughts on How to Perfectly Blend Welds

Understanding The Importance Of Blending Welds For A Perfect Finish

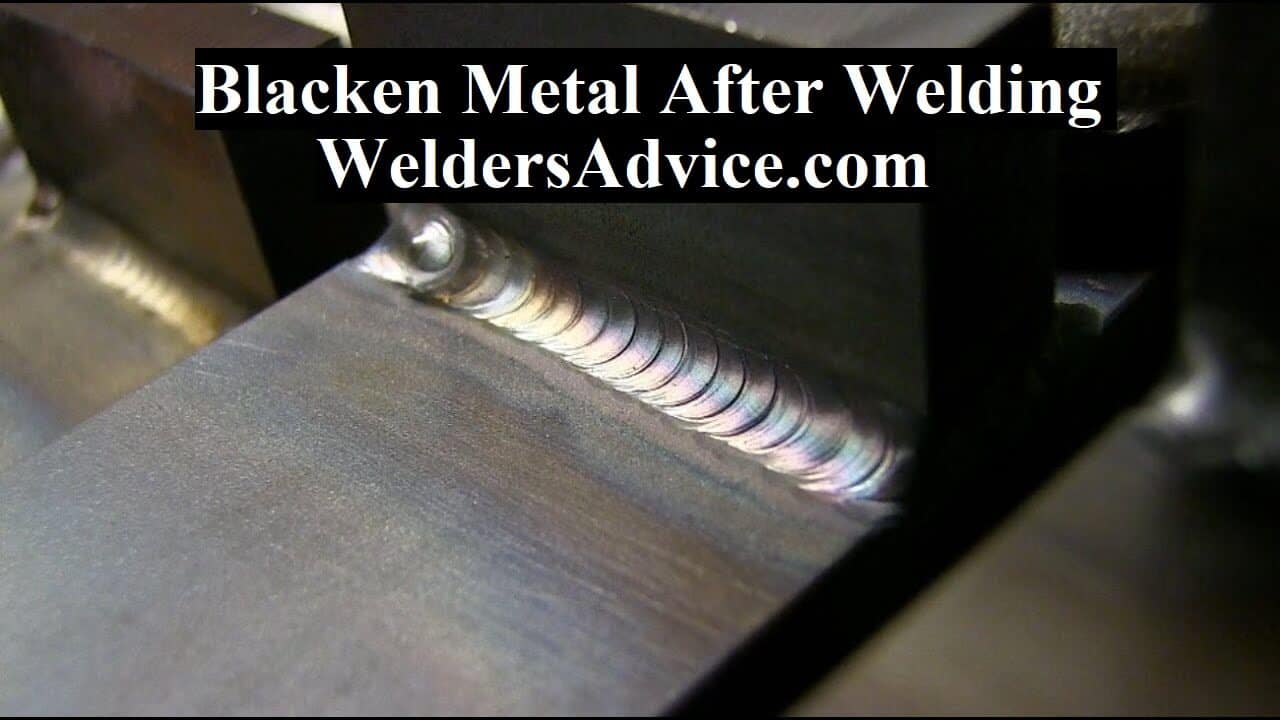

Blending welds is vital for a professional finish. It strengthens and enhances durability by creating smoother, more even surfaces. Expert techniques, like grinding, sanding and buffing, are essential for achieving the best results. Furthermore, blended welds create aesthetically pleasing surfaces that meet the highest standards.

When done correctly, weld blending minimizes the risk of corrosion, cracks, and other problems that could undermine the integrity of the weld joint. The result is a weld joint that looks like it was always there, effectively masking the joint, and enhancing the longevity and reliability of the structure being welded.

Essential Tools And Materials For Blending Welds

Blending welds is a crucial step in achieving a polished finish. To do it right, you’ll need the right tools and materials. Choosing high-quality abrasives, sanders, and grinders is crucial for success. Abrasives should be chosen based on the metal’s type and thickness.

Flap discs are excellent for removing excess metal, and sanding belts can smooth out any rough edges. Sanders come in various sizes and shapes, so select one that meets the job’s requirements. A right-angle grinder with a flap disc attachment works well for most applications.

The materials used for blending welds should be of high quality, as cheaper alternatives may produce poor results. When equipped with the right tools and materials, blending welds can be efficient and produce flawless results.

Step-By-Step Guide To Blending Welds Like A Pro

Blending welds can be tricky, but with the right techniques, you can achieve a smooth and even finish. To begin, focus on minimizing defects and irregularities. It’s essential to achieve the perfect grind angle and pressure for the best results.

Start by using a flap disc to grind down the weld and create a smooth surface. Move on to using a sanding disc to achieve a finer finish. Be sure to thoroughly clean the area before painting or coating. With these tips, you can blend your welds like a pro and give your finished product a polished and professional appearance.

Advanced Techniques For Perfectly Blending Welds

Blending welds is not easy, but advanced techniques and specialty tools make it achievable. Pre-weld surface preparation is critical to obtaining seamless welds. Optimizing welding conditions like voltage, amperage, and wire feed settings can also help minimize the need for blending.

Specialty tools like tungsten carbide burrs, flap discs, and belt sanders are useful for blending. However, equipment alone is not enough; mastering the technique requires patience and skill. By starting with a smaller blending area and gradually increasing it, and adjusting the blending angle, you can effectively and accurately blend your welds.

With the right tools and techniques, you can achieve seamless welds that are not only functional but visually appealing as well.

What Are The Benefits Of Blending Welds?

Blending welds helps to create a more professional look to the welded part. It also helps to remove any defects or imperfections on the surface which can reduce the risk of corrosion or other issues.

What Tools Are Needed For Blending Welds?

Tools for blending welds include angle grinders, flap discs, and sanding discs. You can also use a belt sander or a polishing wheel depending on the requirements of the task.

What Techniques Can Be Used For Blending Welds?

There are several techniques for blending welds including using grinding and sanding discs, a sandblaster, or a wire brush. Each technique has its advantages and disadvantages.

Can Beginners Learn How To Blend Welds?

Yes, beginners can learn how to blend welds. It is essential to follow proper safety precautions, start small, and practice on scrap metal before working on important projects. With proper diligence, anyone can learn how to blend welds.

Final Thoughts on How to Perfectly Blend Welds

Blending welds is a crucial aspect of welding processes as it determines the quality and aesthetics of the final product. By following the tips described in this article, you can make the process smoother, faster, and more efficient. First, ensure that the welds are properly cleaned and ground to remove any surface imperfections.

Second, use the correct angle and pressure when grinding to avoid over-grinding or under-grinding. Third, choose the appropriate abrasive discs to get the desired finish. Fourth, practice blending welds on scrap metal before working on the actual project to hone your skills.

Lastly, always wear protective gear and take safety precautions while working with welding equipment. By incorporating these guidelines, you can produce high-quality welds that blend seamlessly, resulting in a professional-looking finished product.