Welding Galvanized Steel requires special safety precautions due to the presence of zinc in the steel. Which can produce hazardous fumes when heated. Zinc oxide must be removed from the work area before welding. And protective clothing should always be worn.

Before any welding takes place, it is important to clean off any rust or dirt on the surface of the galvanized steel with a wire brush or grinder; this helps prevent weld defects like porosity and cracking. It is also necessary to use electrodes specifically designed for aluminum/zinc alloys when performing MIG (metal inert gas) or TIG (tungsten inert gas) welding operations on galvanized steel. Finally, it is recommended to inspect all welds after completion to ensure they are strong enough for their intended purpose.

Welding galvanized steel can be a tricky process, as it requires special techniques to ensure that the welds are strong and secure. To prevent oxidation of the weld area and contamination from zinc fumes, an inert gas shield should always be used when welding this material. Additionally, pre-heating is important to reduce brittleness in the welded joint.

Properly done, welding galvanized steel can provide strong joints with excellent corrosion resistance for many years.

Can Welding Galvanized Steel Kill You

Welding galvanized steel can be hazardous to your health. As it releases zinc oxide fumes which contain high levels of toxic metals. These fumes are known to cause a wide range of respiratory and neurological problems in exposed workers. Some cases even result in death.

Therefore, it is important to take the necessary safety precautions when welding galvanized steel. This includes wearing appropriate protective gear such as an approved respirator mask and gloves.

Mig Welding Galvanized Steel Settings

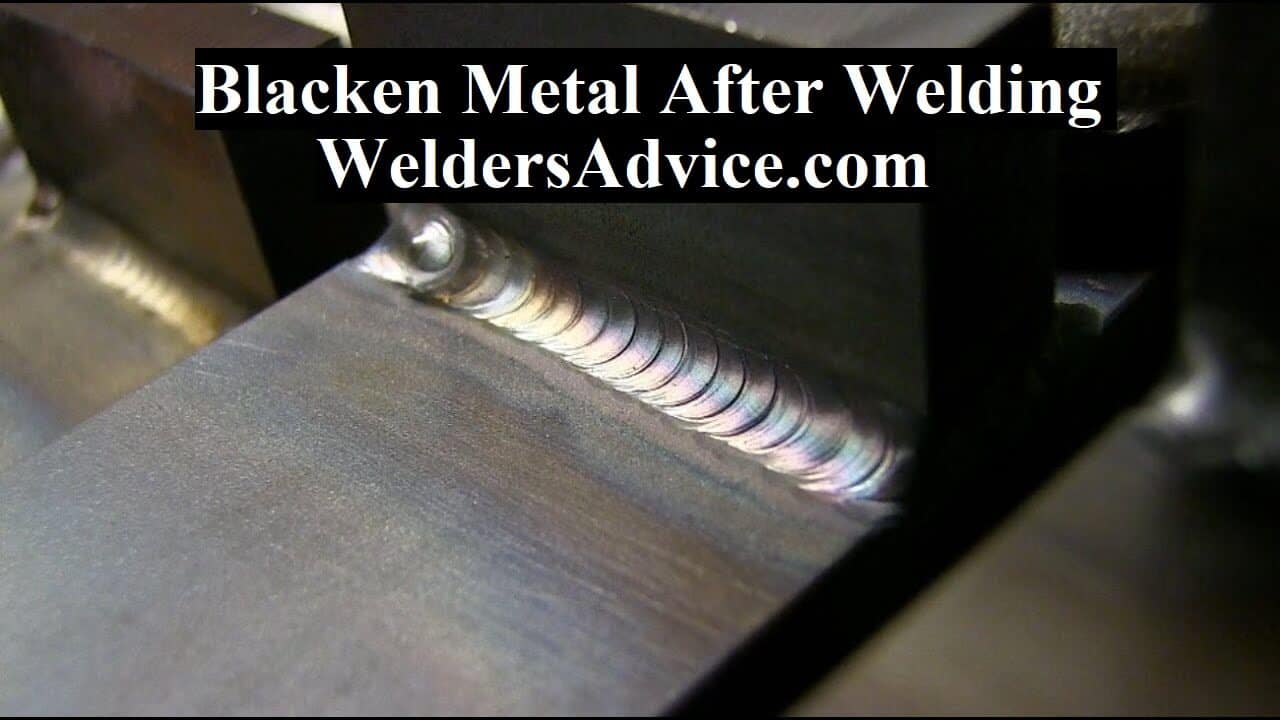

Mig welding galvanized steel requires special settings to ensure a successful weld. For best results, use an Argon-rich shielding gas and set the voltage between 18 and 24 volts. The amperage should be set to around 200 amps with a wire feed speed of approximately 400 inches per minute.

A 0.035-inch diameter wire should be used in order to reduce spatter and produce clean welds. Additionally, preheating the material is recommended for better penetration and less distortion when welding galvanized steel with MIGs.

Welding Rod for Galvanized Steel

A welding rod for galvanized steel comes in different sizes and shapes. With each size designed to meet particular requirements. The most popular types are 6010, 6011, 7018, and 7024 rods. Which contain flux-coated electrodes that help reduce spatter while providing an even stronger weld than traditional stick welding.

This steel requires special care when welding to ensure the integrity of the finished product; failure to use the right kind of rod could lead to cracks or weak spots in your welds.

Galvanized Steel Health Risks

Galvanized steel is a popular material used in construction and other projects. However, it can present health risks when exposed to humans. When galvanized steel corrodes or wears away, small particles of zinc oxide are released into the air which can be inhaled. These particles have been linked to adverse health effects such as respiratory irritation and difficulty breathing, although long-term studies suggest that these effects may not be permanent.

Welding Galvanized Pipe

Welding galvanized pipe requires special precautions to ensure a successful weld. Due to the presence of zinc in the steel, it is important that all surfaces are properly cleaned before welding and that proper shielding gases be used during welding. Additionally, pre-heating can help reduce zinc fumes and create a stronger weld.

Lastly, post-weld cleaning should always take place after the welding job is complete in order to maintain optimal safety standards.

Why Do You Drink Milk After Welding Galvanized?

It releases zinc oxide fumes. Which can be dangerous to breathe in. If you have been welding galvanized steel. It is advisable to drink milk immediately afterward. This is because the calcium present in the milk binds with the zinc oxide fumes and neutralizes their toxicity. Thus reducing any potential harm they may cause when breathed in.

Read More Here: Why Do Welders Drink Milk

Additionally, drinking milk after welding galvanized metal helps reduce irritation of the throat and lungs. That might otherwise occur due to inhaling these hazardous gases.

Furthermore, dairy products contain nutrients like vitamin D and B12 as well as proteins. That is beneficial for your body’s health overall. So even if you haven’t been exposed to any harmful fumes from welding galvanized steel. Drinking a glass of cold milk after a long day of work will still give you all those essential nutrients!

What is the Best Way to Weld Galvanized Metal?

Welding galvanized metal can be a tricky process, as the zinc coating found on galvanized metals can create toxic fumes when heated. To avoid this type of hazard, the best way to weld galvanized metal is to use an inert gas shield around the welding area. This method prevents oxygen from reaching the hot metal and reacting with it, thus eliminating any dangerous fumes.

Inert gases like argon or helium are often used for this purpose because they are chemically stable. And non-reactive at high temperatures. When using an inert gas shield, however, make sure that your equipment is in good condition. And that you have adequate ventilation in your workspace.

Additionally, use a smaller wire size than what is usually recommended for steel. Since too large a wire will increase heat buildup. Which can damage both the material being welded and nearby components.

Finally, exercise caution when moving away from welding areas. So that you don’t accidentally ignite any flammable materials due to residual heat left in the vicinity of where you were working!

What Type of Welding is Best for Galvanized Steel?

MIG welding is often considered the best type of welding for galvanized steel. This process utilizes a wire that acts as an electrode. Which is then passed through a shielding gas such as argon or carbon dioxide in order to create an arc between it and the metal being welded. The resulting heat melts both the base material and the wire, creating a strong bond between them once they cool down again.

MIG welding offers several advantages over other types of welding when working with this, including high productivity rates due to its relatively fast speed; minimal clean-up since no flux is required for this type of process; good penetration into thick sections of galvanized steel; and less spatter due to the inert nature of shielding gases used. Additionally, MIG welds are known for their excellent strength and durability even when exposed to harsh environments or corrosive materials.

Final Thoughts

In conclusion, welding galvanized steel can be a tricky process, but with the right preparation and safety precautions it is an achievable task. It requires patience and knowledge of proper technique to get the job done correctly. If you are unsure how to go about welding galvanized steel, consider consulting with a professional in order to ensure that your project is completed safely and properly without any complications.