If you are in the metalworking industry, you must have come across friction welding at some point. Friction welding is a solid-state welding process that involves the generation of heat through friction between two metal surfaces that are brought together under pressure. The process is widely used in the aerospace, automotive, and manufacturing industries to create high-strength, high-quality joints between different metals. But can you friction weld on a lathe? In this article, we will explore this question and provide you with all the information you need to know.

- Understanding Friction Welding

- Can You Friction Weld on a Lathe?

- How to Friction Weld on a Lathe

- Advantages of Friction Welding

- Materials Suitable for Friction Welding on a Lathe

- Factors to Consider When Friction Welding on a Lathe

- Applications of Friction Welding on a Lathe

- Comparison of Friction Welding on a Lathe with Other Welding Methods

- Friction Welding vs. Fusion Welding

- Friction Welding vs. Resistance Welding

- Friction Welding vs. Adhesive Bonding

- Friction Welding vs. Laser Welding

- Safety Precautions for Friction Welding on a Lathe.

- Conclusion

Understanding Friction Welding

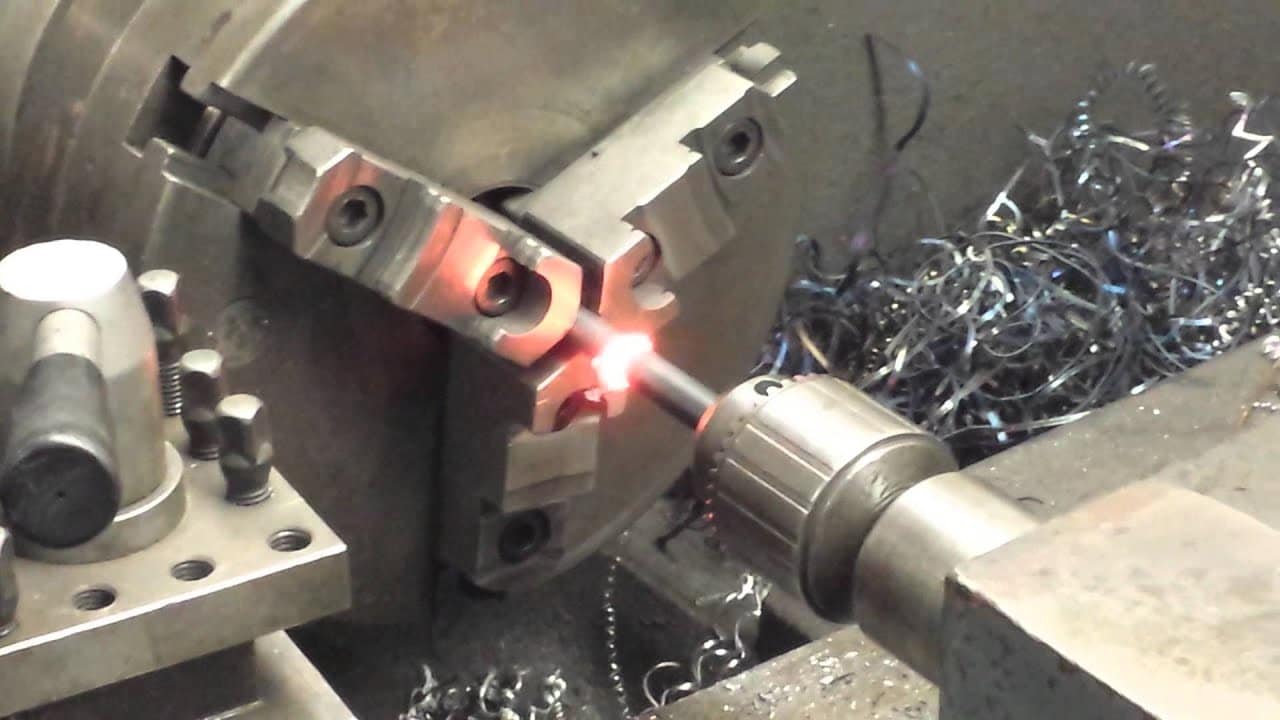

To answer the question of whether friction welding can be performed on a lathe, it’s important to first understand the process of friction welding. Friction welding involves two components, a stationary component and a rotating component, which are brought together under pressure.

The rotation of one component generates friction between the two, causing the metal to heat up and soften. Once the metal is sufficiently softened, pressure is increased, and the two components are forged together. Friction welding is ideal for welding dissimilar metals, and it generates localized heat, resulting in minimal distortion of the surrounding material.

Can You Friction Weld on a Lathe?

Now that we understand how friction welding works, the question remains: can you friction weld on a lathe? The answer is yes, but it’s not a straightforward process.

A lathe is a machine that rotates a workpiece on its axis to perform various operations, such as cutting, drilling, and shaping. Friction welding, on the other hand, involves two rotating components being brought together under pressure.

The problem with using a lathe for friction welding is that the stationary component needs to be held in place while the rotating component is spun at high speeds. This means that you would need to modify the lathe to hold the stationary component securely, which can be a complicated process.

How to Friction Weld on a Lathe

If you’re up for the challenge, here are the steps to follow to friction weld on a lathe:

- Modify the lathe to hold the stationary component securely.

- Identify the rotating component that you want to weld to the stationary component.

- Spin the rotating component at high speeds.

- Bring the rotating component and the stationary component together under pressure.

- Increase the pressure until the two components are forged together.

Advantages of Friction Welding

Now that we know that it is possible to friction weld on a lathe let’s take a look at the advantages of this process. Friction welding offers several benefits over traditional welding methods, including:

Stronger joints: Friction welding creates high-strength joints that are comparable to or better than those produced by traditional welding methods.

Minimal distortion: Since friction welding is a localized heating process, there is minimal distortion of the surrounding material.

Environmentally friendly: Friction welding produces no fumes or gases, making it an environmentally friendly option.

Reduced costs: Friction welding requires no consumables such as gas or filler materials, which can significantly reduce costs.

Materials Suitable for Friction Welding on a Lathe

Friction welding on a lathe is a versatile and effective process that can be used to join a wide range of materials. Some of the materials that are suitable for friction welding on a lathe include:

Steel: Friction welding on a lathe can effectively join steel components, making it a popular choice for a variety of applications in the automotive, aerospace, and manufacturing industries.

Aluminum: Friction welding is also commonly used to join aluminum components, especially in the automotive and aerospace industries. The process is ideal for joining dissimilar metals like steel and aluminum.

Copper: Friction welding can also be used to join copper components, making it a popular choice for electrical and electronic applications.

Titanium: Friction welding on a lathe can be used to join titanium components, which is a popular material in the aerospace and biomedical industries due to its high strength and biocompatibility.

Nickel alloys: Friction welding on a lathe can be used to join nickel alloys, which are commonly used in high-temperature applications such as gas turbines.

It is important to note that not all materials are suitable for friction welding on a lathe, and the process should only be used for materials that can withstand the high temperatures and pressures generated during the process.

Factors to Consider When Friction Welding on a Lathe

When using friction welding on a lathe, there are important factors that need to be considered to ensure a successful welding process. These factors include material selection, component design, machine setup, surface preparation, and weld quality testing.

Materials

The materials used for friction welding on a lathe must be able to withstand the high temperatures and pressures generated during the process.

Component Design

Component design is also important, as irregularly shaped or uneven surfaces may require additional preparation before welding.

Machine setup

Proper machine setup is critical to ensure that the machine is calibrated to the correct speed, pressure, and other variables for the specific materials being welded.

Surfaces

To achieve a strong and reliable bond, the surfaces of the components being welded must be clean and free from contaminants.

Quality testing

Such as visual inspections and non-destructive testing, should be conducted to ensure that the weld meets the required standards.

Applications of Friction Welding on a Lathe

Friction welding on a lathe has numerous applications in various industries. Here are some examples:

Aerospace

Friction welding on a lathe is commonly used in the aerospace industry to join components made from different materials such as aluminum, titanium, and nickel alloys. This method is particularly useful for producing strong, lightweight structures.

Automotive

Friction welding on a lathe is used in the automotive industry to join components. Such as axles, drive shafts, and steering components. The process is also suitable for welding dissimilar metals, such as aluminum to steel.

Electrical and Electronics

Friction welding on a lathe can be used to join copper components, making it a popular choice for electrical and electronic applications.

Medical

Friction welding on a lathe is used in the medical industry to join components made from biocompatible materials such as titanium. This method is particularly useful for producing complex medical devices with high strength and biocompatibility.

Manufacturing

Friction welding on a lathe is used in various manufacturing applications, such as producing hydraulic cylinders, pistons, and other components that require high strength and reliability.

Comparison of Friction Welding on a Lathe with Other Welding Methods

Friction welding on a lathe is a welding technique that offers several advantages over traditional welding methods. Here is a comparison of friction welding with some popular welding methods:

Friction Welding vs. Fusion Welding

MIG and TIG welding uses high heat to melt and join materials. Which can cause distortion and warping of the welded material. In contrast, friction welding generates heat locally, resulting in minimal distortion and preserving the strength of the surrounding material.

Friction Welding vs. Resistance Welding

Resistance welding applies pressure and current to the materials being joined to create a bond. This method is effective for joining some materials but can struggle with dissimilar metals. In contrast, friction welding is a versatile method that can easily join dissimilar materials.

Friction Welding vs. Adhesive Bonding

Adhesive bonding relies on glues and adhesives to join materials. While it is simple and effective for some applications, it is not as strong or durable as friction welding. Friction welding produces a strong, permanent bond without the need for additional materials.

Friction Welding vs. Laser Welding

Laser welding is a precise method that works well for joining small, intricate components. However, it can be a slow and expensive process, and it is not suitable for all materials.

Safety Precautions for Friction Welding on a Lathe.

Friction welding on a lathe can be performed safely by taking proper precautions. Here are some safety measures that should be considered:

- Use appropriate personal protective equipment (PPE), such as gloves, eye protection, and flame-resistant clothing.

- Ensure that the lathe is in good working condition and well-maintained before beginning the welding process.

- Make sure that the workpiece is securely held in the lathe. And that there is no potential for it to become loose during the process.

- Avoid touching any moving parts of the lathe or welding equipment while in operation.

- Keep a fire extinguisher nearby in case of accidental ignition of the workpiece or other materials.

- Ensure the work area is properly ventilated to prevent inhalation of fumes or gases generated during the welding process.

- Use the lathe only for its intended purpose. And do not modify or alter it in any way that could compromise its safety.

Conclusion

In conclusion, while it is possible to friction weld on a lathe, it’s not a straightforward process. Friction welding involves two rotating components being brought together under pressure. And modifying a lathe to hold the stationary component securely can be a complicated process. However, if you’re up for the challenge, friction welding offers several benefits over traditional welding methods. Including stronger joints, minimal distortion, and reduced costs.