To bleed off a welding oxygen tank, slowly turn the valve counterclockwise until all pressure is released. This can be done with the use of a pressure gauge to ensure that the tank is completely emptied.

Bleeding off the tank is a safety measure that must be taken before any maintenance or storage is performed on the tank. Failure to properly release pressure can lead to injury, damage to equipment, and even explosions. It is crucial to follow proper safety procedures when handling welding oxygen tanks to prevent potential hazards.

In this article, we will discuss step-by-step instructions on how to bleed off a welding oxygen tank safely and efficiently.

- The Basics Of Welding Oxygen Tanks

- Signs That Your Oxygen Tank Needs Bleeding

- How To Bleed Your Oxygen Tank

- Best Practices For Maintaining Your Oxygen Tank

- What Happens If You Don’t Bleed Off A Welding Oxygen Tank?

- How Often Should You Bleed A Welding Oxygen Tank?

- Final Thoughts on Bleed Off a Welding Oxygen Tank

The Basics Of Welding Oxygen Tanks

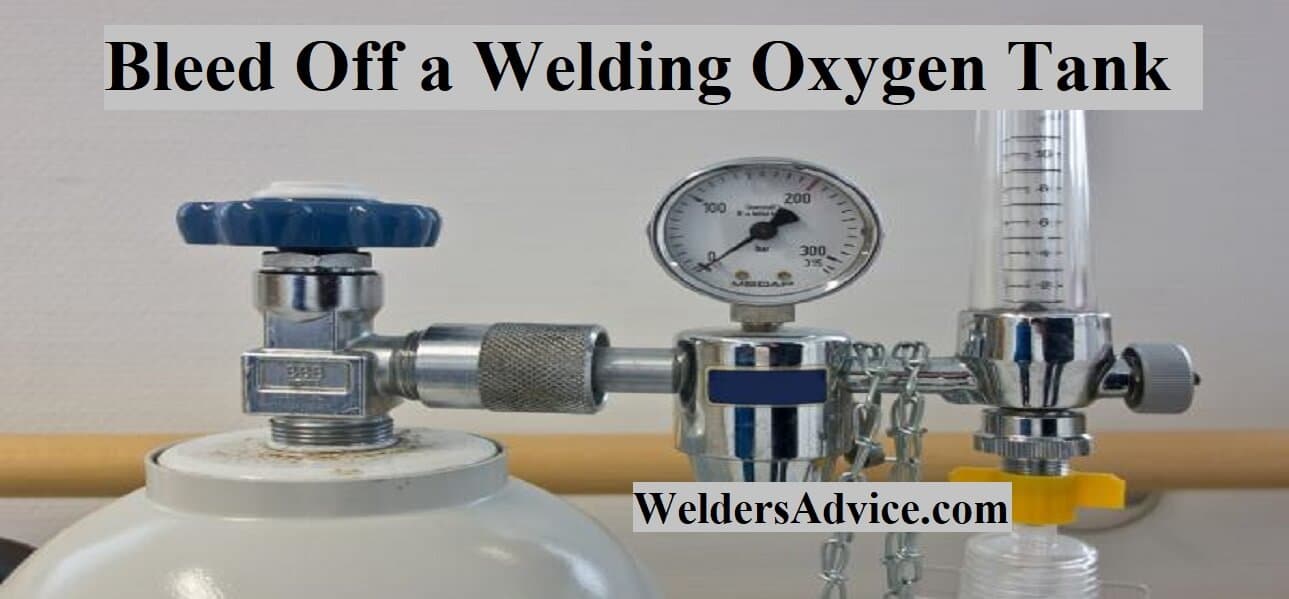

The basics of welding oxygen tanks are essential for welding work, and it’s key to know the basics to avoid accidents when working with one. An oxygen tank mainly comprises a cylinder, a gauge, a regulator, and a valve.

The cylinder stores the oxygen under pressure, the gauge indicates the amount of oxygen in the tank, the regulator controls the tank’s pressure, and the valve releases the oxygen. The mechanics of an oxygen tank are simple; the tank is filled with oxygen at high pressure, and when the valve releases, the pressure escapes, carrying the oxygen with it.

Oxygen tanks should be handled with care, no matter how small they are, and safety guidelines should be followed rigorously.

Signs That Your Oxygen Tank Needs Bleeding

Identifying when your welding oxygen tank needs to be bled is crucial for safety. Signs include: decreased flame intensity and difficulty lighting the torch. Not bleeding can lead to the accumulation of contaminants, compromising regulator performance and risking a fire or explosion.

Bleeding should be done after every use, and periodically during prolonged storage. Ensure you have proper ventilation, protective gear, and a fire extinguisher when attempting to bleed the tank. Remember to always be cautious when dealing with flammable gases under high pressure.

How To Bleed Your Oxygen Tank

Bleeding off a welding oxygen tank is an essential safety precaution for welders. Follow these steps to do it correctly. First, make sure the tank is properly secured and ventilated. Open the valve slowly to release the pressure and allow the gas to escape.

Pay attention to the hissing sound and wait until it stops before closing the valve. To get the most from your oxygen tank, keep it in a clean and dry area, and store it in an upright position. When bleeding your tank, remember to wear proper safety gear, including gloves and eye protection.

By following these guidelines, you can safely and effectively bleed your oxygen tank and maintain its longevity.

Best Practices For Maintaining Your Oxygen Tank

Properly storing and transporting your welding oxygen tank is crucial to maintaining its functionality. When storing your tank, make sure it is secured upright and away from any heat or combustible materials. When transporting it, use a secure vehicle and do not let it roll or bounce around.

Clean your tank regularly with a damp cloth and avoid using any harsh chemicals or oils. Check for any damages or leaks before using it, and always wear protective gear when handling it. Bleeding off the tank is also important to prevent contamination and ensure a steady supply of oxygen.

Follow these best practices to properly maintain your oxygen tank and ensure safe and efficient welding.

What Happens If You Don’t Bleed Off A Welding Oxygen Tank?

If you don’t bleed off a welding oxygen tank, pressure can build up in the tank, which can cause it to burst. This could cause injury to anyone nearby and damage to equipment. Bleeding the tank ensures that you release any pressure built up inside, which will help prevent any potential injury or damage.

How Often Should You Bleed A Welding Oxygen Tank?

Welding oxygen tanks should be bled regularly to prevent the build-up of pressure and hazards. Industry-standard recommends bleeding the tank every time you finish using it, but also bleeding off any trapped air during the mid-course of its usage. The tank should also be bled if it’s been sitting unused for an extended period or is dropped.

Final Thoughts on Bleed Off a Welding Oxygen Tank

Properly bleeding off a welding oxygen tank is crucial for the safety of the welder and the equipment. You can perform the process quickly and efficiently by following a few simple steps. Start by opening the valve to reduce the pressure in the tank, then attach the regulator and release the gas until it reaches zero pressure.

Ensure to remove the regulator and replace the valve cap once the tank is empty. With the right precautions and attention to detail, the bleeding process can be carried out without incident. Remember to always follow safety procedures when stopping the flow of oxygen, and don’t hesitate to seek assistance if you’re unsure about any aspect of the procedure.

By following these tips, you can safely and effectively bleed off your welding oxygen tank, keeping your workspace safe and ready for the next job.