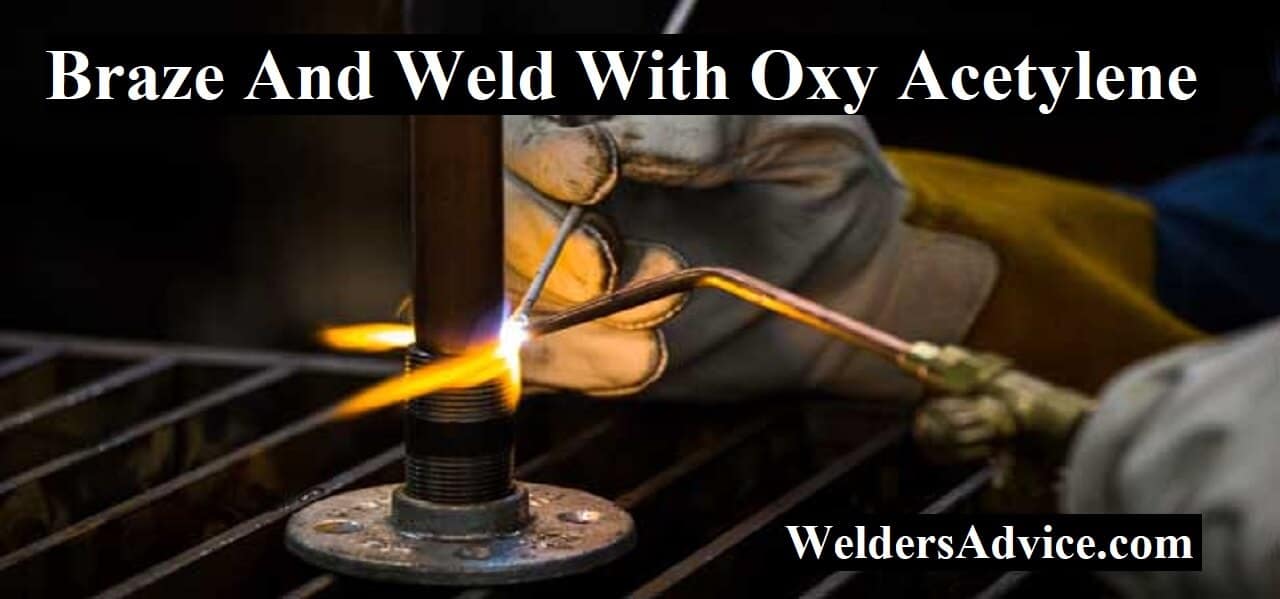

To braze and weld with oxy acetylene, you need to master the correct techniques and safety measures. In this guide, we will discuss the steps and tips to execute a proper oxy acetylene welding.

Oxy acetylene welding is a process that involves joining metals together with the help of heat and a filler metal. This technique has been used for many years, and it is still widely used in industrial applications. However, it can be a challenging process if not done correctly.

To begin with, welding requires a stable work surface, proper protective equipment including gloves, masks, and safety glasses. Before starting, make sure that all components are clean and free of contaminants. Once everything is in place, ignite the oxy acetylene flame, ensuring that the flame is not too long or too short by adjusting the pressure and flame size. Next, start brazing or welding by heating the workpiece with the flame and introducing the filler material. Move the torch over the plate in a circular motion and at a consistent speed, ensuring that the flame is always at the right angle and distance. After the welding is complete, allow the piece to cool down naturally. With the right tools, techniques, patience, and care, anyone can learn how to braze and weld with oxy acetylene.

- What Is Oxy Acetylene Welding?

- What Is Oxy Acetylene Brazing?

- The Key Differences Between Oxy Acetylene Welding And Brazing

- Preparing For Oxy Acetylene Welding

- Conducting Oxy Acetylene Welding

- Understanding Different Welding Techniques And Applications

- Preparing For Oxy Acetylene Brazing

- Conducting Oxy Acetylene Brazing

- Understanding Different Brazing Techniques And Applications

- Understanding Industrial Applications For Oxy Acetylene Welding And Brazing

- How To Choose The Right Materials And Equipment For Industrial Oxy Acetylene Welding And Brazing

- Frequently Asked Questions For How To Braze And Weld With Oxy Acetylene

- Final Thoughts on Braze And Weld With Oxy Acetylene

What Is Oxy Acetylene Welding?

Oxyacetylene welding is a welding process using heat generated by a flame. This process produces temperatures of around 6,000 degrees Fahrenheit, melting and fusing two metals together. The equipment needed for this process is an oxy-acetylene torch, a gas welding rod or wire, and filler material.

Oxy acetylene welding has advantages, such as versatility and portability, but also has disadvantages, including the need for proper ventilation and higher safety precautions. To successfully braze and weld with oxyacetylene, it is important to understand the process, the equipment needed, and the advantages and disadvantages of using this method.

Whether you’re a beginner or a seasoned welder, oxy acetylene welding is a great skill to add to your welding repertoire.

What Is Oxy Acetylene Brazing?

Oxy acetylene brazing is a process used to bond two metal pieces together. It involves heating the joint with an oxy-acetylene torch, causing it to reach a melting point, and then adding a filler material. This filler material is melted by the heat of the torch, flows into the joint, and creates a permanent bond.

To get started, you’ll need an oxy-acetylene torch, filler material, and metal pieces to bond. Oxy acetylene brazing has several advantages, including strong bonds, flexibility, versatility, and durability. However, the process also has some disadvantages, such as the need for proper ventilation, potential safety hazards, and the requirement for skill and experience.

If you want to learn how to braze and weld with oxy acetylene, seek professional guidance or training before attempting it yourself.

The Key Differences Between Oxy Acetylene Welding And Brazing

Oxy-acetylene welding and brazing are two techniques commonly used for joining metal materials. Although they may seem similar, there are significant differences between the two. Understanding these differences is crucial to achieve the desired results. While welding creates a strong, permanent bond between two metals, brazing uses a filler material to join them.

When choosing between welding and brazing, it’s important to consider factors such as the materials being joined, the required strength of the joint, and the application for which it will be used. Whether welding or brazing, it’s important to follow safety procedures and have the appropriate equipment to ensure a successful outcome.

By knowing the differences and choosing the right technique, you can easily and effectively join metals with oxy-acetylene.

Preparing For Oxy Acetylene Welding

To prepare for oxy acetylene welding, you must first set up your workspace. This includes ensuring there is adequate ventilation and removing any potential fire hazards. Understanding the safety precautions is crucial, such as using protective equipment and having a fire extinguisher nearby.

Additionally, you should gather all necessary materials and equipment beforehand, such as the welding torch and filler rods. Finally, ensure all materials are clean and free of any contaminants that could affect the weld’s quality. With proper preparation, you can confidently begin the oxy acetylene welding process.

Conducting Oxy Acetylene Welding

Oxy acetylene welding is a process that requires precision and patience. To conduct this welding technique, there are specific steps that you must follow to achieve perfect results. Start by assembling the equipment and setting up the work area properly.

Next, light the torch and adjust the flame to the right heat intensity. Remember to wear the proper protective gear to avoid accidents. To ensure perfect welds, you can use a few tricks such as keeping the flame moving and keeping the filler rod at a consistent angle.

However, there are common mistakes you should avoid, such as overheating the metal or leaving gaps in the joint. Overall, with proper preparation and execution, oxy acetylene welding can be a successful welding technique.

Understanding Different Welding Techniques And Applications

Welding can seem daunting, but oxy acetylene welding is a great technique for diy projects. Compared to tig and mig, oxy acetylene welding uses a torch to heat the metal and filler rod that melts to form the weld. With the right technique, you can create clean and strong welds.

First, prepare the metal and clean the area. Next, light the torch and adjust the flame. Then, heat the metal and add the filler rod. Practice makes perfect, so start with simple projects and work your way up. With some effort and patience, you can achieve great results and create beautiful, functional pieces.

Preparing For Oxy Acetylene Brazing

Before starting with oxy acetylene brazing, it is essential to prepare the workspace. Ensure that the area is well-ventilated and free from any flammable substances. Also, understanding the necessary safety precautions is crucial to avoid any accidents. Some safety measures include wearing protective gear, keeping a fire extinguisher nearby and reading the manufacturer’s instructions.

Preparing the materials and equipment ahead of time is also necessary. This includes cleaning and verifying that the materials are free of any oils, dirt or rust. Lastly, ensure that all equipment is in good working condition, including the oxy acetylene torch, hoses and regulators.

Following these steps will guarantee that your brazing project is successful and safe.

Conducting Oxy Acetylene Brazing

Oxy acetylene brazing is a useful skill for welders to learn. To conduct proper brazing, follow these steps: clean and prepare the materials, ignite the torch, adjust the flame, heat the base metal, add the filler metal, and allow the joint to cool.

To ensure perfect brazes, use the correct torch tip and filler metal, keep the flame at the right angle, and maintain steady heating. There are common mistakes to avoid, such as not cleaning the materials properly, overheating or underheating the metals, and using the wrong type of filler metal.

By following these guidelines, you’ll have success with oxy acetylene brazing.

Understanding Different Brazing Techniques And Applications

Brazing and welding with oxy acetylene is a useful skill for diy enthusiasts. Soft soldering is ideal for small, delicate work. Brazing is more durable and excellent for joining different metal components. Welding is the recommended technique for building or fixing heavy-duty projects.

Each technique requires different equipment and skills. When brazing: use tongs to hold metal in place and avoid overheating. Safety is key when working with oxy acetylene, always wear protective gear. Remember, patience and practice is essential for perfecting this skill.

Start with a simple project and gradually progress to more complex ones. Happy brazing!

Understanding Industrial Applications For Oxy Acetylene Welding And Brazing

Oxy acetylene welding and brazing are extensively used in various industrial applications. Manufacturers and fabricators in industries like construction, automotive, and aviation rely on its precision and strength. The process involves heating two metal parts and melting a filler metal to bond them.

This method is ideal for areas that are hard to reach or even for repairing metal equipment and structures. Each industry has a unique requirement, and oxy acetylene welding and brazing are customized to fulfill those needs. For example, the aviation industry mostly uses oxy acetylene welding for aluminum structures, whereas the automotive industry primarily uses it for bodywork.

Understanding the need for this process in different industries can open up numerous job opportunities for welders and fabricators.

How To Choose The Right Materials And Equipment For Industrial Oxy Acetylene Welding And Brazing

Industrial oxy acetylene welding and brazing requires expert precision and experience, as well as the right materials and equipment. Choosing the correct materials is essential to ensure structural integrity and durability, while the right equipment makes the work easier and more efficient.

In order to select the right materials, knowledge of their properties, strengths and weaknesses is key. Understanding the differences between materials and why they are used for specific applications is vital to executing successful welds and brazes. The right equipment, including welders, torches, regulators and other accessories, must also be chosen based on the job requirements.

By carefully selecting the right materials and equipment, industrial oxy acetylene welding and brazing can be executed safely and effectively, producing the desired results.

Frequently Asked Questions For How To Braze And Weld With Oxy Acetylene

What Is Oxy-Acetylene Welding?

Oxy-acetylene welding is a welding process that uses a mixture of oxygen and acetylene gas to create a hot flame that can be used to join metals.

What Are The Safety Precautions While Oxy-Acetylene Welding?

Some safety precautions to take while oxy-acetylene welding include wearing personal protective equipment (ppe), properly ventilating the workspace, and keeping a fire extinguisher handy.

What Are The Advantages Of Oxy-Acetylene Welding?

Oxy-acetylene welding is a versatile process that can be used to weld a variety of metals, it is portable and can be used in remote locations, and it allows for precise control over the heat and welding process.

What Are The Disadvantages Of Oxy-Acetylene Welding?

Some disadvantages of oxy-acetylene welding include that it is a slower process compared to other welding methods, it produces a lot of heat and sparks, and it requires specialized equipment and training to use safely and effectively.

Final Thoughts on Braze And Weld With Oxy Acetylene

By following the guidelines outlined in this article, anyone can learn to braze and weld with oxy acetylene. It’s important to remember to always prioritize personal safety, use the correct equipment and technique, and to practice and perfect your skills.

Whether you’re a diy enthusiast or a professional welder, oxy acetylene is a versatile and useful welding method that can help you complete a wide range of projects. With patience, practice, and a dedication to learning, anyone can become skilled in oxy acetylene welding and brazing.

So why not give it a try? Who knows, you may just discover a new passion and skillset that you can use for years to come.