To braze weld copper pipes, clean the surface of the pipes, apply flux paste, heat the joint, and introduce the brazing rod.

Copper pipes are widely used in plumbing projects as they are durable, long-lasting, and resistant to corrosion. Braze welding is a commonly used technique to join copper pipes as it creates a strong, leak-proof bond. However, it is essential to follow some basic steps to ensure a successful braze weld.

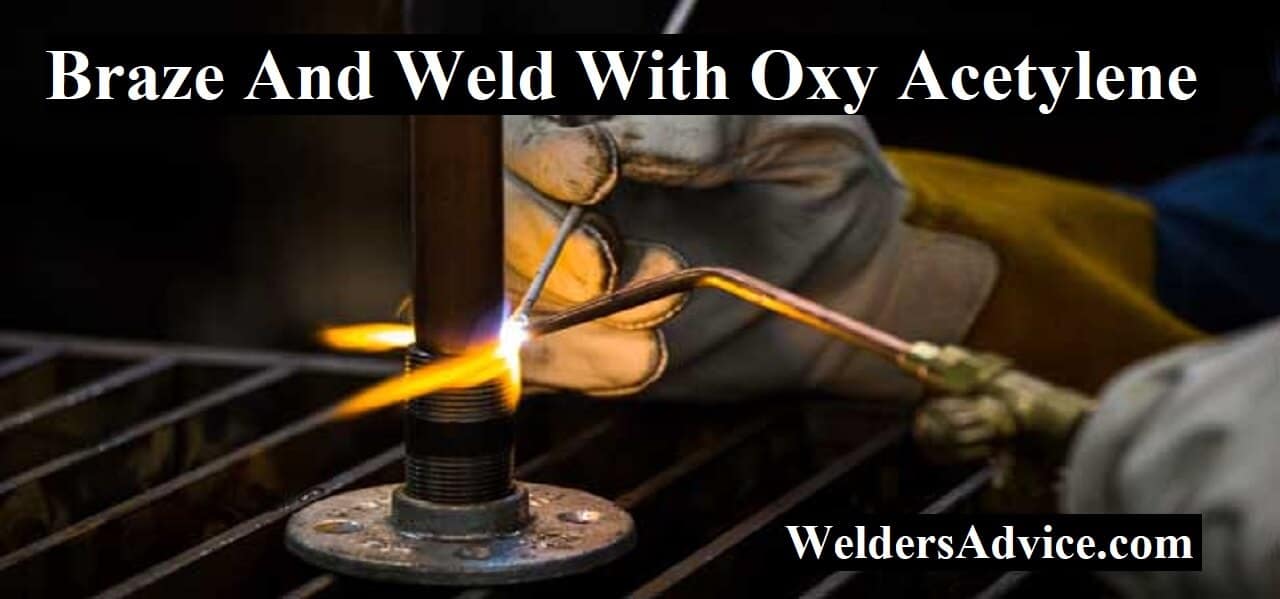

This includes cleaning the surface of the pipes, applying flux paste to promote adhesion, heating the joint with a torch until it reaches the correct temperature, and introducing the brazing rod. In this article, we will walk you through the steps to braze weld copper pipes accurately and efficiently.

- Understanding The Basics Of Braze Welding Copper Pipes

- Preparing Copper Pipes For Braze Welding

- Steps For Braze Welding Copper Pipes

- Troubleshooting Common Issues In Braze Welding Copper Pipes

- Frequently Asked Questions On How To Braze Weld Copper Pipes

- What Safety Measures Should I Follow While Braze Welding Copper Pipe?

- Can I Braze Weld Copper Pipes Without Flux?

- Final Thoughts

Understanding The Basics Of Braze Welding Copper Pipes

Braze welding copper pipes is a process of joining pipes using a brass filler metal. This process is different from welding as it requires heating the metal beyond its melting point. The brass filler metal liquefies, and when it cools down, it forms a strong bond between the copper pipes.

In addition to the copper pipes and the brass filler metal, several tools and equipment are required, including a propane torch, flux, a wire brush, and safety gear such as gloves and goggles. It is essential to take good safety precautions when brazing welding copper pipes to prevent accidents or injuries.

This includes ensuring proper ventilation, wearing protective gear, and keeping a fire extinguisher nearby. With proper safety measures in place, you can successfully braze weld copper pipes to create a strong and reliable connection.

Preparing Copper Pipes For Braze Welding

To begin the process of preparing copper pipes for braze welding, it is important to inspect the pipes for any defects or damage. If any issues are found, they must be addressed before continuing. Next, the copper pipes must be cleaned thoroughly to remove any dirt, debris, or grease.

Cutting the pipes to the desired length is the next step. Once the pipes have been cut, it is necessary to deburr the edges to prevent clogging. With these steps completed, the copper pipes are now ready for braze welding.

By following these guidelines, you can ensure that the braze welding process goes smoothly and the copper pipe connection is strong and secure.

Steps For Braze Welding Copper Pipes

- Before you begin your braze welding project, you need to have the right type of brazing filler metal.

- Next, apply flux to the copper pipes, which will help remove any oxidation.

- Ensure the copper pipes are properly assembled and secure before you start the heating process.

- Be sure to apply heat to the assembly evenly using a torch or other heating tool.

- Finally, apply the brazing filler metal to the copper pipes.

Follow these steps carefully to ensure a strong and effective braze weld on your copper pipes.

Troubleshooting Common Issues In Braze Welding Copper Pipes

Troubleshooting common issues in braze welding copper pipes is crucial to ensure successful weld joints. One of the issues encountered is uneven heating during the braze welding process. This can lead to an uneven flow of filler material and cause weak joints.

Porosity issues in the braze welding joint can also arise when contaminants are present. Joint failure due to incomplete braze welding happens when the joint surfaces are not clean or oxides are present. To avoid these issues, proper cleaning and preparation of surfaces, selecting the right filler material, and using an even heat source are key.

Additionally, ensuring that the joint is sealed properly and free of contaminants can help prevent porosity in the joint.

Frequently Asked Questions On How To Braze Weld Copper Pipes

What Is Braze Welding Of Copper Pipe?

Braze welding is a process of joining two pieces of copper pipe with a third, melted filler metal.

What Type Of Torch Is Required For Braze Welding Copper Pipe?

A propane torch with a trigger start is ideal for braze welding copper pipe.

What Is The Ideal Temperature For Braze Welding Copper Pipe?

The ideal temperature for braze welding copper pipe is around 1400°f.

What Safety Measures Should I Follow While Braze Welding Copper Pipe?

Wear heat-resistant gloves, safety goggles, and protective clothing while braze welding. Ensure good ventilation and keep a fire extinguisher nearby.

Can I Braze Weld Copper Pipes Without Flux?

Flux is essential for braze welding copper pipe as it prevents oxidation and ensures proper bonding of the filler metal.

Final Thoughts

So, that’s all folks. We have learned how to braze weld copper pipe. It’s a skill that every plumber or DIY enthusiast should have in their toolbox. Remember to follow all the necessary safety measures such as wearing safety glasses and gloves.

You need to prepare the pipes properly before brazing and use a suitable filler metal to ensure a strong bond. Practice with scrap pieces of metal before attempting to braze welding copper pipes in your plumbing project. Lastly, take your time and be patient, brazing welding copper pipes is an art that requires practice and patience.

With these tips, you should be well on your way to a successful copper pipe braze welding project. So good luck!