To braze weld light gauge steel exhaust pipes, use a propane torch and flux-coated brazing rods. First, clean the metal surfaces you are welding and then evenly heat the area.

Apply the brazing rod and allow it to melt and flow into the joint evenly. Brazing welding light gauge steel exhaust pipes is a technique required to repair a crack, hole, or break in the pipe. A high-quality braze weld can help to create a professional and long-lasting seal.

It is especially important to brazing weld light gauge steel pipes correctly since they have thinner walls and can overheat easily, causing warping and distortion. The ideal equipment for this type of welding includes a propane torch as well as flux-coated brazing rods. You will need to care for the welding area, heat it evenly, and apply the brazing rod to obtain uniform penetration.

- What Is Braze Welding?

- Difference Between Braze Welding And Other Welding Techniques

- Steps to Braze Weld Light Gauge Steel Exhaust Pipes

- Selection Of Materials

- Cleaning And Surveying

- Setting Up The Equipment

- Applying The Filler Metal

- Avoiding Warping And Distortion

- Managing The Heat Input

- Tacking The Exhaust Pipes

- Welding The Exhaust Pipes

- Cleaning The Weld

- Inspecting The Weld

- Frequently Asked Questions For How To Braze Weld Light Gauge Steel Exhaust Pipe

- What Kinds Of Tools And Materials Do I Need For Braze Welding Light Gauge Steel Exhaust Pipes?

- What Are Some Tips For Achieving A Successful Braze Weld On Light Gauge Steel Exhaust Pipes?

- Do I Need Any Special Training Or Certifications To Braze Weld Light Gauge Steel Exhaust Pipes Safely And Effectively?

- Final Thoughts on Braze Weld Light Gauge Steel Exhaust Pipes

What Is Braze Welding?

Braze welding is a joining process that involves melting a filler metal at high temperatures, which then flows into the joint and forms a strong bond. Unlike other welding methods that use heat to melt the base metals, braze welding relies on the filler metal to hold the joint together.

This makes it an ideal process for light gauge steel exhaust pipes as it doesn’t distort or warp the thin metal. Furthermore, braze welding has several advantages over other welding methods, including the ability to join dissimilar metals, excellent corrosion resistance, and high-strength joints.

With the right tools, equipment, and expertise, braze welding can be a simple and effective way to repair or fabricate exhaust pipes for cars and motorcycles.

Difference Between Braze Welding And Other Welding Techniques

Braze welding is a preferred technique for light gauge steel. Compared to other welding techniques such as tig and mig, it offers a unique set of advantages. Firstly, it is a low-temperature welding process hence it does not adversely impact the metal’s properties.

Secondly, braze welding works well for dissimilar metals and thin gauges. Tig welding, for instance, requires a high skill level, which makes it unsuitable for small or hard-to-reach areas. Braze welding also creates an aesthetically pleasing, clean weld that is easy to manipulate.

Steps to Braze Weld Light Gauge Steel Exhaust Pipes

While there are other welding processes available, braze welding is the preferred method for light gauge steel exhaust pipes because of its strength, versatility, and low-heat input.

Selection Of Materials

When brazing welding light gauge steel exhaust pipes, materials selection is vital. Choosing the appropriate filler metal and flux is critical for the success of the job. The selection process requires assessing factors such as the temperature range, joint type, welding position, and base metals’ composition.

Additionally, consider the joint’s strength requirements, corrosion resistance, and the welding environment’s cleanliness. Matching the filler metal’s composition with the joining metals is also essential to ensure proper bonding. Welders should avoid using too much flux, leading to poor brazing.

The right materials combination ensures a robust, durable, and aesthetically pleasing assembly. Therefore, welders must take sufficient time to evaluate the materials before commencing the brazing process.

Cleaning And Surveying

To braze weld light gauge steel exhaust pipes, cleaning and surveying are crucial steps. Begin by thoroughly cleaning the welding area to ensure a strong bond. Survey the pipes for any deformities, such as cracks or damages, to correct them before welding.

This not only enhances the durability of the exhaust pipes but also allows for better performance. Taking care of these details during the preliminary stages guarantees a successful braze weld. While handling exhaust pipes, it’s important to prioritize safety measures, such as using protective gear.

Remember to double-check everything before proceeding to the next step.

Setting Up The Equipment

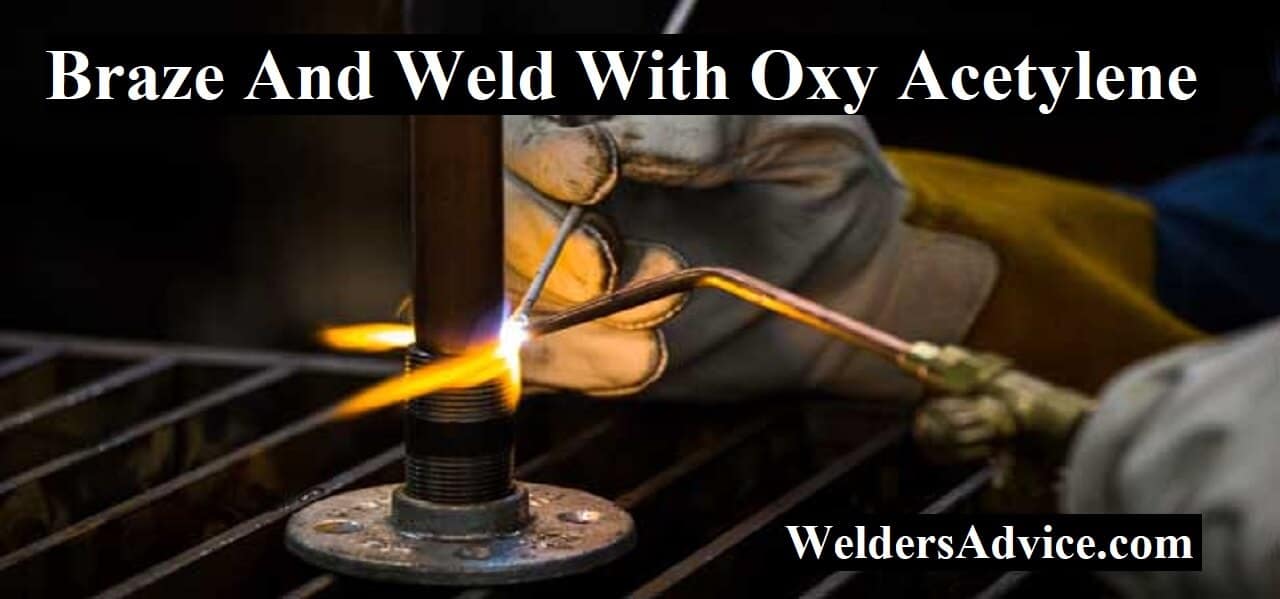

Brazing welding light gauge steel exhaust pipes require proper equipment setup. First, set up the oxygen and acetylene torch. Check the torch valves and regulators to ensure they are in good condition. Adjust the flame and flow rate accordingly. A neutral flame with a blue inner cone is ideal for brazing.

Maintain a steady flame while brazing to prevent warping or melt-through of the exhaust pipe. Remember to wear proper safety gear to prevent accidents. Good equipment setup ensures a successful braze weld on light gauge steel exhaust pipes.

Applying The Filler Metal

The key to successful braze welding of light gauge steel exhaust pipe is applying the filler metal correctly. Follow these techniques for a smooth experience: first, start with a tightly fixtured joint. Second, use a small amount of filler metal while carefully and consistently applying heat.

Third, control the heat so as to melt just the filler metal, without melting the exhaust pipe. Finally, avoid excessive filler metal accumulation by applying it in small doses. With this method, the heat balance and metal flow should be stable, eliminating the risk of a weak joint or unsightly buildup.

Practice these techniques often to achieve a successful braze weld every time!

Avoiding Warping And Distortion

Welding light gauge steel exhaust pipe can cause warping and distortion. This is due to high heat input, poor welding techniques, and improper preparation. To avoid these issues, use a slow welding process, clamp the metal in place, and pre-heat the pipe to prevent temperature shock.

Another technique is to use a pulse arc welder or a spot welder instead of a standard mig welder. Be sure to also clean the pipe thoroughly before welding to avoid contamination. Following these steps can help you create a strong, durable weld without warping or distortion.

Managing The Heat Input

Managing the heat input is crucial when brazing welding light gauge steel exhaust pipe. The importance of controlling the heat input cannot be overstressed in this process. Excess heat will distort the pipe or create pinholes in the weld. To manage heat input, use a flame that is appropriately sized for the pipe’s thickness.

The ideal flame will heat the pipe and the filler metal simultaneously. Controlling the amount of heat applied to the pipe during welding can be done by adjusting the flame’s distance, angle, intensity, and direction. Keep checking the color of the heated pipe; a straw yellow color indicates that it is at the correct temperature for welding.

By following these recommendations for managing heat input, you can obtain a good braze weld on light gauge steel exhaust pipes for your projects.

Tacking The Exhaust Pipes

Brazing welding may seem daunting, but tacking your exhaust pipes is easier than you think. By following these guidelines, you’ll be able to track your pipes in a place like a pro. First, ensure that your pipes are properly aligned. Use a clamp to keep them in position to avoid any misalignment.

Second, make sure you’re using the correct thickness of welding wire. This will help prevent any gaps in your tack welds. Third, clean the joint area with a wire brush to remove any rust or debris. Fourth, use a tacking sequence to maintain the pipes’ proper alignment.

Fifth, tack weld every inch of the pipes to provide a strong support structure. Proper tacking ensures a solid foundation for the welding process, leading to a sturdy and long-lasting exhaust system.

Welding The Exhaust Pipes

When welding light gauge steel exhaust pipes, there are techniques to keep in mind. First, ensure both pipes are thoroughly cleaned before welding. Next, make sure you have the correct filler rod for the job. When welding, it’s important to keep a steady hand and maintain the correct temperature.

One common mistake is welding in short bursts, which can lead to a weak weld. Another mistake is using too much weld material, which can cause warping. To avoid these issues, use a consistent speed and apply a small amount of weld material at a time.

Following these tips will help ensure a strong and long-lasting weld on your exhaust pipes.

Cleaning The Weld

Cleaning the weld is a crucial step in braze welding light gauge steel exhaust pipes. To effectively clean the welded area, start by removing any excess filler metal. Use a wire brush or grinder to clean the surface of the weld and surrounding areas.

Cleanliness is key when it comes to welding, as any contaminants can weaken the bond. Make sure to eliminate any oil, grease, or other debris by wiping the area with a clean cloth or solvent. After this, inspect the area to ensure that it is completely clean and free of any debris.

Proper cleaning is vital to ensure a strong, long-lasting weld.

Inspecting The Weld

Checking for defects can prevent future issues. Look for cracks, porosity, undercut, and cold joints. To correct these defects, consider grinding, welding, or brazing.

Grinding can remove surface defects. Welding or brazing can fill porosity, cracks, and undercut. To prevent defects, avoid overheating the joint and use the proper flux. Reviewing each weld after completion ensures a smooth process and quality product. By carefully inspecting and correcting any defects, you can produce a strong and reliable braze weld on your light gauge steel exhaust pipe.

Frequently Asked Questions For How To Braze Weld Light Gauge Steel Exhaust Pipe

What Are The Benefits Of Using Braze Welding For Light Gauge Steel Exhaust Pipes?

Braze welding is ideal for light gauge steel exhaust pipes because it creates a strong joint without warping or distorting the pipes. It’s also a relatively easy and affordable process that doesn’t require specialized equipment or training.

What Kinds Of Tools And Materials Do I Need For Braze Welding Light Gauge Steel Exhaust Pipes?

To braze weld light gauge steel exhaust pipes, you’ll need a brazing torch, flux, brazing rods, cleaning supplies, a grinder, and safety equipment. Make sure to choose tools and materials that are specifically designed for the type of metal you’re working with.

What Are Some Tips For Achieving A Successful Braze Weld On Light Gauge Steel Exhaust Pipes?

Before braze welding, thoroughly clean and prepare the surfaces to be joined. Apply flux to the joint area, heat the metal with the torch, and add filler metal. Move quickly and evenly to avoid overheating or burning the metal. Let the joint cool slowly to prevent cracking or brittleness.

Do I Need Any Special Training Or Certifications To Braze Weld Light Gauge Steel Exhaust Pipes Safely And Effectively?

While it’s always a good idea to seek training or guidance from a professional, you don’t necessarily need a certification to braze weld light gauge steel exhaust pipes. However, make sure to follow all safety guidelines and work in a well-ventilated area to avoid inhaling toxic fumes.

Final Thoughts on Braze Weld Light Gauge Steel Exhaust Pipes

As we conclude, braze welding light gauge steel exhaust pipes is not only possible but also an effective way of repairing them. The process involves cleaning the area to be repaired, preparing the rod and the torch, applying the brazing rod, and finally grinding the surface.

With the right tools, procedures, and safety measures, you can confidently repair your light gauge steel exhaust pipes and have them functioning optimally. Remember to use the recommended safety gear and ensure that you have a well-ventilated workspace. Additionally, it would be best to have a professional check the overall condition of the exhaust system periodically.

We hope that this guide has been informative and that you can confidently put the knowledge into practice. Happy braze welding!