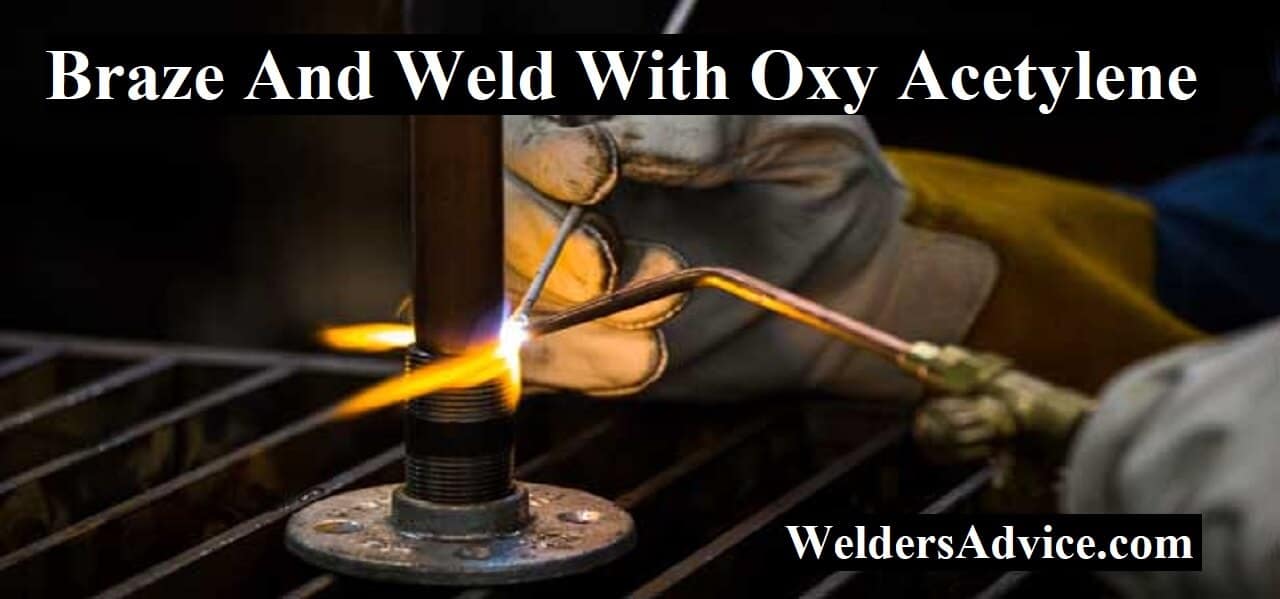

To Braze weld mild steel requires the use of a brazing rod and a torch. Clean the surfaces to be brazed, heat the metal with the torch, and apply the brazing rod to the joint until it melts and flows, forming a strong bond.

Brazing welding is a metal joining process that involves the use of a filler metal that melts at a higher temperature than the base metal. This process is commonly used to join two or more pieces of metal that cannot be welded by conventional welding methods.

Mild steel is a popular material used in manufacturing because of its strength and ductility. In this article, we will discuss the steps involved in brazing welding mild steel, the materials required, and the safety precautions that need to be taken.

Braze Welding Vs. Other Welding Techniques In Mild Steel

Braze welding is a technique used to join metals that require lower temperatures than traditional welding. It’s different from other welding methods in that it involves melting of a filler metal, which flows into a joint by capillary action, rather than melting the base metal.

Due to its lower heat input, braze welding is a suitable option for mild steel. It’s ideal for thin and delicate materials or those that require a lower temperature for joining. While braze welding has its benefits, it also has some drawbacks, such as less strength and not suitable for high-stress applications.

However, for the right project, using braze welding can provide effective results. Understanding the difference between braze welding and other welding methods is vital when selecting the right technique for mild steel projects.

Essential Tools And Equipment For Braze Welding Mild Steel

Braze welding mild steel requires a set of essential tools. Your toolkit should include a gas torch, flux, silver brazing rods, safety glasses, and a fire extinguisher. Various options of welding equipment are available in the market, including torches, gases, and filler metals.

Using the correct size of brazing rod is also crucial. Choose the right equipment by identifying the type and thickness of your metal, and the ultimate use of your work. Your equipment should be in excellent condition to prevent malfunctions, and you will need to ensure that it is suitable for working with mild steel.

By adhering to these guidelines, you will have all the necessary tools and equipment to produce strong, high-quality braze weld joints.

Prepping And Setting Up For Braze Welding Mild Steel

To braze weld mild steel, the first step is to clean and prepare the metal surface. Use a wire brush to remove any rust or debris. Next, choose the best flux for your project, considering factors like joint strength and heat tolerance.

Setting up the work area is critical, and you must prioritize safety. Use proper ventilation and wear protective equipment like gloves and goggles. Once you’ve prepped and set up, it’s time to start braze welding. Heat the metal with a torch until it’s hot enough to melt the brazing rod.

Then, apply the brazing rod to the joint and keep the metal hot until the rod melts. Once it has cooled and solidified, you’re ready to move on to the next joint. With these steps in mind, you’ll be well on your way to braze welding mild steel like a pro!

Mastering The Art Of Braze Welding Mild Steel

Braze welding mild steel might seem challenging for beginners, but with patience, practice, and precision, anyone can master this technique. To achieve a clean and strong weld, you should follow some tips and tricks. Troubleshooting common problems is part of the learning process too.

Don’t rush the heating process, take your time to reach the right temperature. Always clean the surface before welding, and don’t forget to use the right flux and filler metal. If the joint isn’t perfect, don’t worry; you can file, grind, or sand it to achieve the desired shape.

Keep in mind that practice makes perfect!

What Safety Precautions Should Be Taken When Braze Welding?

To ensure safety when braze welding, wear protective equipment such as goggles, gloves, and aprons. Work in a well-ventilated area and use a respirator if necessary. Keep a fire extinguisher nearby and never work with flammable materials or gases near an open flame.

What Are The Advantages Of Braze Welding?

Braze welding offers several advantages, including a strong joint, the ability to join dissimilar metals, the ability to join thin metals, and the ability to create a clean joint without the need for extensive preparation or finishing. It is also a relatively simple and cost-effective process.

Final Thoughts on Braze Weld Mild Steel

It’s evident that braze welding mild steel is a critical skill for welders to have in their toolbox. By following the step-by-step process, you can ensure that your braze weld is strong, aesthetically pleasing, and durable. Remember to clean the metal surface thoroughly and prep before welding.

Follow these tips for a smooth and efficient braze weld. Always wear protective gear, work in a well-ventilated area, and avoid overheating. The key to successful braze welding is finding the right filler metal, adjusting the torch flame, and keeping a steady hand.

Keep practicing, and with time, you will master this skill. By mastering the art of braze welding, you can open up new possibilities for your welding projects, build long-lasting structures, and create beautiful pieces of art.