To braze weld sheet metal, first, clean the metal surfaces, apply flux, heat the metal, and then apply the brazing rod. Braze welding can be done with a torch, furnace, or induction heater.

It provides strong, durable joints that are resistant to corrosion and wear. Braze welding is a method of joining two metal surfaces by heating them to a temperature above their melting point and then applying a filler metal that has a lower melting point.

This process is commonly used to join sheet metal, which is thin and difficult to weld with traditional welding techniques. Braze welding provides a strong and durable joint that is resistant to corrosion and wear. It is especially useful for joining dissimilar metals, such as copper and stainless steel. In this article, we will discuss the steps involved in braze welding sheet metal.

Understanding Brazing And Welding Sheet Metal

Brazing and welding sheet metal may seem similar but have significant differences. Brazing is the process of joining metal parts using a filler that melts and solidifies to form a strong bond. Welding, on the other hand, involves melting the metal parts to be joined.

Techniques for fabricating sheet metal include cut-and-bend, roll-forming, stamping, and deep drawing. Each technique requires different skills and tools to produce quality results. Sheet metal comes in different types such as stainless steel, aluminum, copper, brass, and carbon steel.

Each metal type has unique properties and requires specific welding or brazing techniques for optimal results. By understanding the difference between brazing and welding and employing the appropriate techniques, you can successfully fabricate sheet metal and produce quality products.

Preparing To Braze And Weld Sheet Metal

Before brazing welding sheet metal, proper safety measures must be identified and followed. The right equipment, such as a torch and filler rod, must also be obtained. Preparing the surface of the metal is imperative, with cleaning and smoothing as top priorities.

Avoid using words or phrases that are overused, and keep sentences brief yet understandable. Using varied phrases and expressions can also keep the reader interested. There is no need to add a conclusion paragraph, as the information provided is direct and informative.

Brazing Sheet Metal

Brazing sheet metal is a process of joining two or more pieces of metal using a filler metal, which melts and flows into the joint. The filler metal should have a lower melting point than the metal being joined. There are different types of brazing techniques available, such as torch brazing, furnace brazing, and induction brazing.

To achieve successful brazing, it is important to clean the metal surfaces thoroughly, use the correct filler metal, and maintain the appropriate temperature during the process. Additionally, it is crucial to ensure that the joint is strong and durable. By following these tips, you can master the art of braze welding sheet metal and create strong, long-lasting joints for various applications.

Welding Sheet Metal

Welding is an essential process of joining metals together. Different techniques are employed to bond sheet metal, including laser, gas, and tig welding. To ensure successful welding, clean the metal surface and select the appropriate filler metal. Keep the heat low and work in sections, making sure to remove any impurities.

Use proper protective gear, and practice beforehand. Welding sheet metal requires skill and patience. But with the right technique, you can achieve a seamless and sturdy bond. Don’t forget to double-check your work and seek professional assistance if needed.

Frequently Asked Questions For How To Braze Weld Sheet Metal

What Is Braze Welding, And How Does It Differ From Regular Welding?

Braze welding is a process of joining metals using a filler metal that has a lower melting point than the metals being joined. Unlike regular welding, braze welding doesn’t melt the base metals, but instead uses heat to melt the filler metal, which then flows into the joint to bond the pieces together.

What Types Of Metals Can Be Braze Welded?

A wide range of metals can be braze welded, including stainless steel, copper, brass, and various alloys. However, the process is primarily used for joining thin sheets of metal, such as those used in automotive panels or HVAC systems.

What Equipment Do I Need To Braze Weld Sheet Metal?

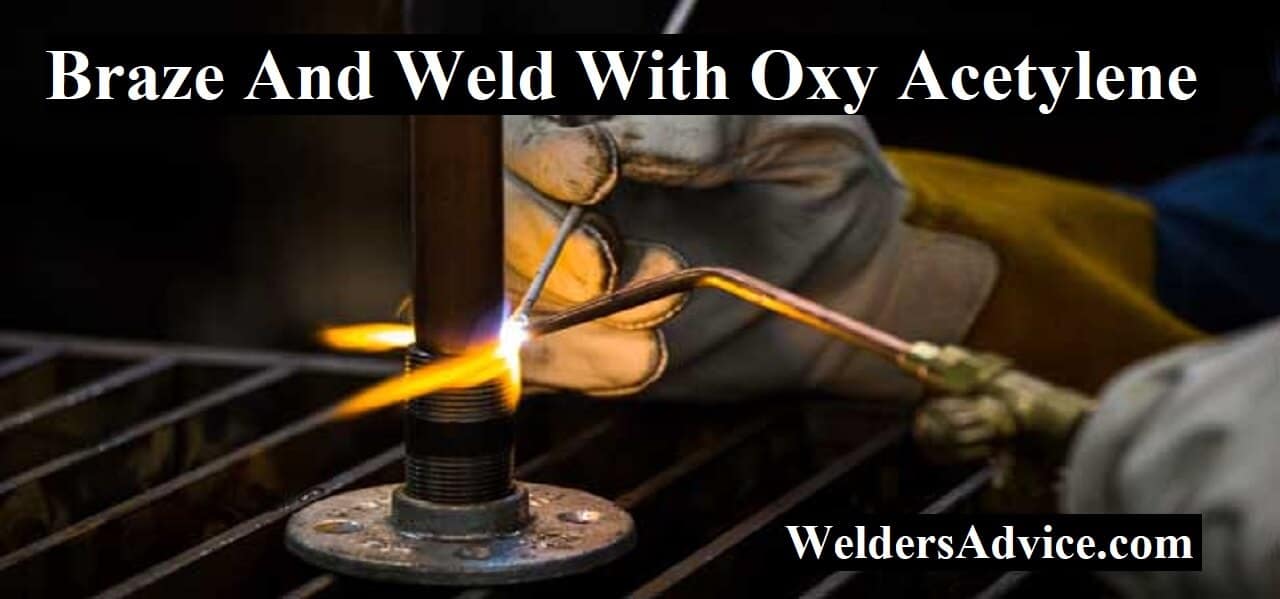

To braze weld sheet metal, you’ll need a torch (either oxyacetylene or propane), a filler metal (such as a brazing rod or wire), a flux (to help clean and prepare the joint), and appropriate safety gear, such as goggles and gloves.

How Do I Prepare The Sheet Metal For Braze Welding?

Before braze welding, you’ll need to clean the joint thoroughly to remove any dirt, grime, or oils. Then, apply flux to the joint to help it bond. After heating the joint with your torch, use your filler metal to “flow” the braze into the joint, taking care not to overheat the metal and cause warping or damage.

Do I Need Special Training To Braze Weld Sheet Metal?

While it’s not strictly necessary to have special training to braze weld sheet metal, it’s certainly helpful. At a minimum, you should be familiar with the safety procedures involved in using a torch and handling hot metal. Additionally, you’ll need to practice your technique to get consistent and reliable results.

Final Thoughts on Braze Weld Sheet Metal

Brazing welding sheet metal may seem like an intimidating task, but with the right tools and techniques, it can be done easily and efficiently. Remember to choose the right type of brazing filler metal depending on the base metal you are working with.

Take your time to clean and prepare the surfaces properly before brazing, and adjust the flame on your torch according to the thickness and size of your workpiece. With practice, you’ll be able to achieve clean, strong, and aesthetically pleasing brazed welds on your sheet metal projects.

Remember to also prioritize safety by wearing the appropriate protective gear and working in a well-ventilated area. Follow these tips and tricks and you’ll be on your way to mastering the art of brazing welding sheet metal!