To braze weld stainless steel, clean the surfaces to be joined thoroughly and preheat them evenly. Then, apply the brazing filler metal and heat the assembly until the filler melts and bonds the surfaces together.

Brazing welding of stainless steel requires meticulous cleaning of the surfaces to be joined. Smooth joints with minimal gaps are necessary to achieve strength and give the best results. Preheating should be even to prevent warpage and distortion. To achieve a strong and durable joint, use the correct filler metal and flux.

It is imperative to heat the entire assembly uniformly and control the temperature to match the melting point of the filler metal. This process bonds the stainless steel surfaces securely and generates a resistant joint with protection against corrosion. Here are some guidelines to follow while braze welding stainless steel.

Understanding The Basics Of Braze Welding

To effectively braze weld stainless steel, understanding the basics of braze welding is crucial. Different types of welding have strengths and weaknesses that must be evaluated before selecting the right process. The science behind braze welding involves metallurgy and intermetallics.

Before beginning the welding process, careful consideration and preparation must be taken with surface preparation, joint design, and selecting the right filler wire. A clean and tight joint is essential to producing a quality braze weld. With the right techniques and materials, braze welding stainless steel can produce strong and durable joints that are resistant to corrosion.

Tools Of The Trade: Essential Braze Welding Equipment

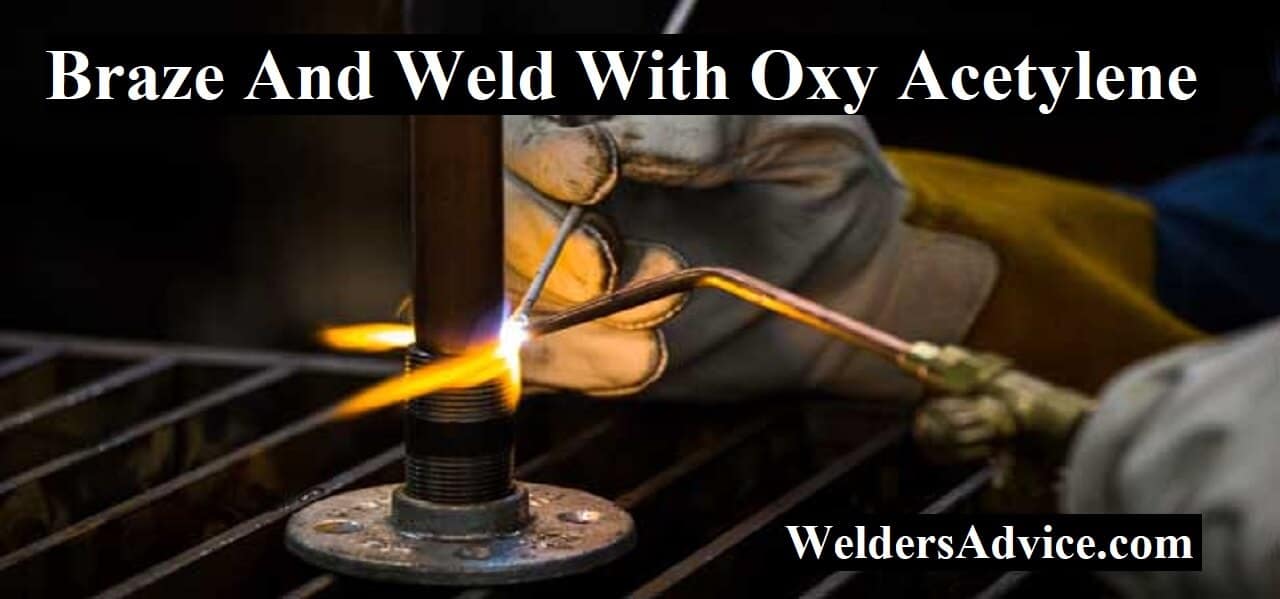

In order to braze weld stainless steel, it’s crucial to select the right equipment. The first essential tool is a torch, either an oxy-acetylene or oxy-propane torch, depending on the job. You’ll also need a brazing rod, which should have the right composition and thickness to match the base metal.

A flux, which cleans the metal and assists the bonding process, is also necessary. It’s important to store your equipment properly to ensure longevity, and to maintain it regularly. This includes cleaning the torch, replacing worn parts, and keeping the brazing rods and flux in air-tight containers.

Braze welding is a precise process, and selecting and maintaining quality tools is key for a successful outcome.

Steps For Perfect Braze Welding

Braze welding stainless steel can be a challenging task for welders due to its properties. However, following these step-by-step guidelines, you can achieve perfect braze welding. Begin by cleaning the stainless steel to remove any dirt or debris. Then select and prepare the appropriate filler material, and ensure the joint fits tightly.

During the welding process, ensure the torch and flame are correctly adjusted to avoid any overheating or burning. If you encounter any issues, use troubleshooting techniques such as examining the joint or adjusting the torch’s angle. Finally, use quality control and inspection techniques to ensure the weld’s integrity and avoid any defects.

With these tips, you can produce a high-quality braze weld on stainless steel.

Techniques And Tips For Mastering Braze Welding Stainless Steel

Braze welding stainless steel requires advanced techniques such as pulse welding and machine brazing. To take your brazing skills to the next level, focus on small tips such as keeping the joint area clean before brazing. Completing complex brazing projects requires focus and attention to detail, as well as the right tools and equipment.

Avoid starting sentences with overused phrases and keep your writing concise and relevant to the topic. By following these tips, you can master the art of braze welding and take on even the most challenging projects with ease.

Frequently Asked Questions For How To Braze Weld Stainless Steel

What Are The Benefits Of Braze Welding?

Braze welding has several benefits. It produces joints with high strength and ductility, it is easy to control the amount of heat used, it requires less preparation of the base materials than other forms of welding, and it allows for easy repair of parts.

Can Stainless Steel Be Braze Welded?

Yes, stainless steel can be braze welded. However, it is important to select the appropriate filler metal to ensure a strong joint. Silver-based filler metals are commonly used for braze welding stainless steel.

What Precautions Should I Take When Braze Welding Stainless Steel?

It is important to work in a well-ventilated area and wear appropriate protective gear such as gloves and a welding helmet. Follow all safety protocols supplied by the manufacturer of your equipment. Additionally, it is important to select the proper filler metal and flux for your project.

Final Thoughts on Braze Weld Stainless Steel

Brazing welding stainless steel can be a challenging task, but the results are worth the effort. The process allows you to create strong and durable welds that can withstand high temperatures and corrosive environments. By following these steps, you can achieve a successful outcome: clean the material properly, use the right filler metal, preheat the base metal, and control the brazing temperature and atmosphere.

Additionally, it’s crucial to practice proper safety precautions, use appropriate protective gear, and work in a well-ventilated area. Remember, brazing welding is an art that requires experience, patience, and attention to detail. With enough practice and dedication, you can master the craft and produce high-quality welds for any stainless steel application.

So, go ahead and give it a try, and let your welding skills shine!