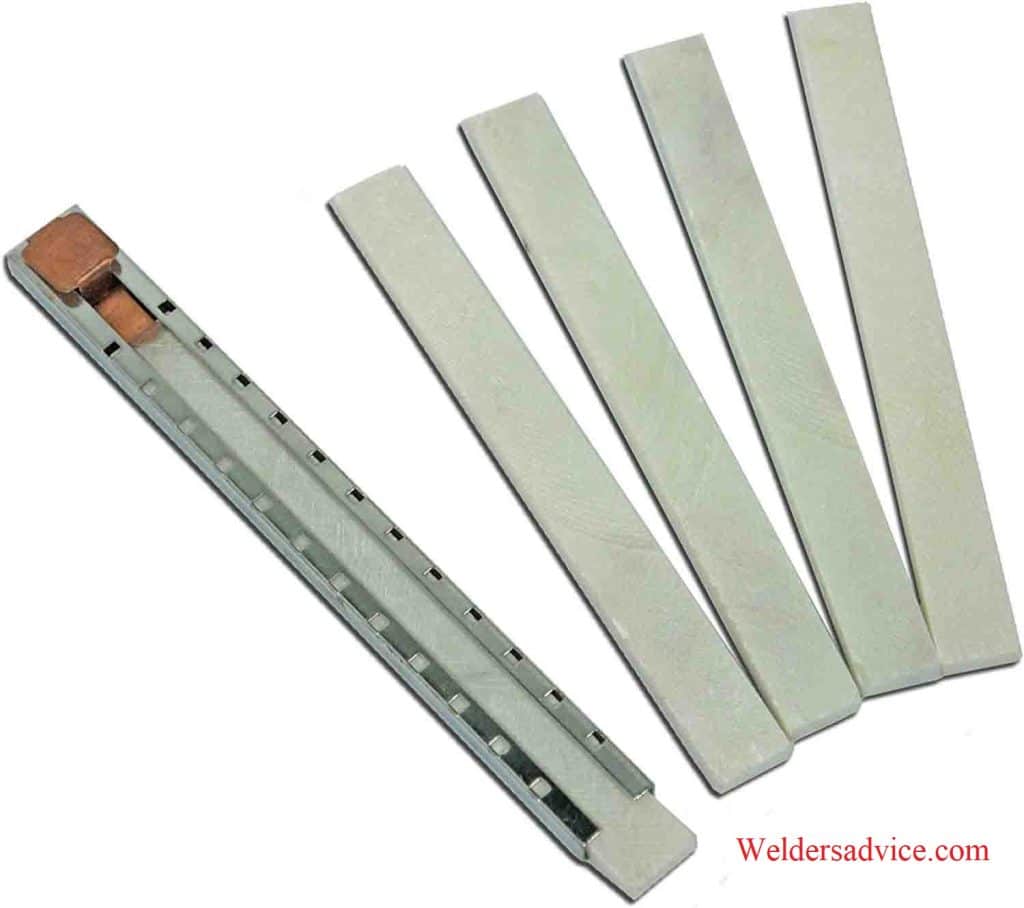

Welders use soapstone as a marking tool for various applications in welding. Soapstone is a soft and pliable stone that can easily mark metal surfaces, making it a popular choice among welders. It is a natural material that is primarily composed of talc and is resistant to heat. Making it an ideal marking tool for high-temperature welding applications.

Soapstone is also easy to use and does not require any additional equipment. Which makes it a cost-effective and convenient option for welders. In this article, we will explore the various benefits of using soapstone in welding. And why it is a must-have tool in every welder’s kit.

Why Do Welders Use Soapstone

Welders use soapstone for marking metal parts and pieces prior to welding. The reason is that it can be used on almost any surface, including stainless steel, aluminum, cast iron, and more. It also has a low melting point. Which allows welders to easily make marks without the risk of damaging the underlying material.

Additionally, soapstone is heat resistant and doesn’t melt during welding operations. Other materials like chalk or pencils might do when exposed to high temperatures. Soapstone also provides an easy-to-read mark that won’t smudge or rub off during the welding process. As well as being very affordable compared to other marking mediums. This makes it ideal for many types of fabrication work. Where precision markings are necessary before beginning assembly or welding tasks.

Welders use soapstone for marking metal surfaces during welding. Soapstone is an ideal tool because its soft texture allows it to make accurate, clean marks without scratching the metal surface. Furthermore, soapstone is resistant to heat. Making it a durable and reliable tool that welders can rely on when working with hot metals.

Additionally, soapstone does not leave any residue behind like other marking tools such as markers or pencils might do.

All of these features make soapstone a preferred choice for welders. Who are looking for an efficient way to mark their workpieces before beginning a job.

Also Read: Best Welding Caps

Why Use Soapstone Instead of Chalk?

Soapstone is an excellent alternative to chalk for use in many different applications. Not only does it have a longer life than traditional chalk. But also, its soft texture makes it much easier to write on. And manipulate without damaging the surface of other materials. Also, soapstone is non-toxic and won’t produce toxic dust when used. Which is ideal for use in any environment where safety and health are a concern.

Additionally, this material can be found in various colors. Allows you to choose a color that best suits your purpose or project. Something that cannot be done with traditional chalk. Soapstone works well with most surfaces including wood and metal. So projects can range from artwork, signage, or even hobbyist tasks such as carving small figurines.

Finally, soapstone provides better contrast than regular chalk against most surfaces. Lines will show up more clearly which makes them easier to read or follow while working on a project.

All these benefits make soapstone an ideal choice over traditional chalk for any application requiring markings on various surfaces.

Does Soapstone Contaminate Weld?

No, soapstone does not contaminate the weld. Soapstone is a type of metamorphic rock made up primarily of talc and quartz. That is often used as a heat-resistant tool in welding. It can withstand temperatures up to 2,000°F (1,093°C) without melting or breaking down.

Because it doesn’t react with other elements when exposed to high temperatures, it won’t contaminate the welded material.

In fact, soapstone can actually help protect the weld from contamination by absorbing contaminants on its surface. Before they make contact with the workpiece being welded. This makes soapstone an ideal choice for use in welding operations. Where cleanliness is essential for producing a quality finished product.

Also Read: Best Flux Core Welders

What is a Soapstone Pencil Used For?

It is most commonly used in the construction industry. Where it can be used to mark out measurements and guidelines on hard surfaces. Such as stone, brick, tile, or concrete. The lead of the soapstone pencil consists of a mixture of talc and wax. Which gives it superior strength when compared to regular graphite or charcoal wood-cased pencils.

Soapstone also has great heat resistance so it won’t melt or deform even when exposed to high temperatures. This makes it an excellent choice for working around welding equipment. Because you don’t have to worry about the marks disappearing due to extreme heat exposure.

In addition, soapstone is non-toxic and safe for use in any environment. Don’t need to worry about hazardous fumes or dust particles getting into your lungs from the burning process.

All these features make a soapstone pencil an invaluable tool for anyone who needs precision markings in their work!

Where Does Welding Soapstone Come From?

Welding soapstone is a commonly used material in the welding industry. It is a soft and non-abrasive stone that helps protect welders from burns caused by molten metal. But where does this unique material come from?

The answer may surprise you: it comes from nature! Welding soapstone can be found in metamorphic rocks, such as quartzite, marble, and slate. The stones are mined and then cut into smaller pieces before they are sold to welding supply stores for use.

This makes them easily accessible to those who need them for their projects. The natural origin of welding soapstone has made it popular among welders. Due to its ability to withstand high temperatures without breaking down or becoming too brittle.

Additionally, it is relatively inexpensive compared to other materials used in the welding process. Making it an attractive option for hobbyists and professionals alike.

So next time you’re looking for something special and unique that can help with your welding project. Consider using the naturally occurring wonder—welding soapstone!

Soft Slag Welding Definition

Soft slag welding is a type of arc welding that uses an electrode to create an electric arc between the electrode and the base material. The heat produced melts both the electrode and base metal, forming a molten pool of weld material. Soft slag welds are typically used on stainless steel due to their ability to fuse together two pieces quickly with minimal spatter or distortion.

This technique offers several advantages over other types of welding processes. Including increased speed, improved safety features such as reduced fumes/spatter, and more precise control over heat input. For better consistency in finished welds.

Can You Weld Over Soapstone

Yes, you can weld over soapstone. As we already discussed, soapstone is a type of metamorphic rock that has been used in welding for centuries. Because it is non-porous and highly heat resistant. This makes it an ideal material to use when welding with high temperatures. As the stone will not be affected by heat or any sparks created during the process.

Additionally, soapstone provides an even surface that helps promote better welds. And reduces the risk of warping or damaging other materials nearby.

Final Thoughts

In conclusion, it is clear why welders use soapstone. Soapstone is a soft mineral that offers many benefits for welding. It can be used to mark metal surfaces, which allows welders to accurately and quickly position their equipment.

The material also helps protect the metals from heat damage, making it an ideal choice for grinding and cutting applications. Soapstone is also easy to clean up after use and does not require additional protection when exposed to high temperatures or sparks due to its non-porous nature. All in all, soapstone makes an excellent tool for any welder’s workshop!