Braze weld steel involves heating the joint and adding filler metal to connect two pieces of metal. Start by cleaning and preparing the surfaces, then apply the filler metal using a brazing torch.

In the world of metalwork, there are several techniques for welding and joining metals. One of the most popular and effective ways of joining steel is through brazing welding. This process involves using a torch to heat the joint and applying a filler metal to connect two pieces of metal.

Unlike other welding techniques, brazing welding works well with dissimilar metals. It also allows for the joining of parts with thin walls without distortion or burn-through. This article will provide a detailed guide on how to braze weld steel, including the tools and equipment required, safety measures to consider, and step-by-step instructions.

Different Types Of Braze Welding

Braze welding is a popular method utilized by metal fabricators. There are numerous braze welding methods available, but oxyacetylene is the most common. It is highly effective in terms of weld quality and speed. The tig welding process offers many advantages over other welding techniques.

It creates very precise welds while maintaining excellent control over plasma. Moreover, tig welding’s high-quality welds require less finishing work. MMA and MIG welding have distinct advantages and disadvantages. MMA welding is simple to use and specifically designed for a diverse range of welds.

Mig welds can be performed faster than MMA and produce better-quality welds for thin materials. The welding process ultimately chooses the method used. Choose a welding method that optimizes both productivity and quality.

Preparing For Braze Welding

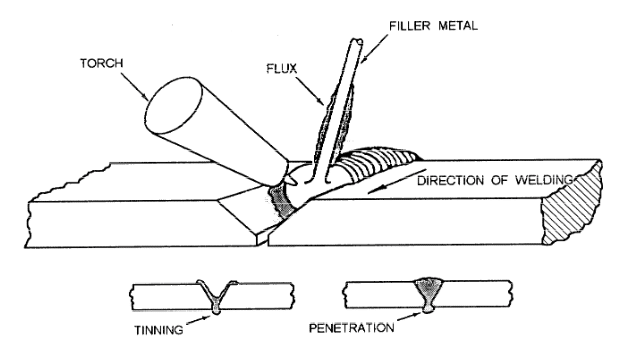

To prepare for braze welding, you must gather the necessary tools and equipment, including a torch, filler metal, and flux. Before beginning the weld, you need to properly clean and prepare the joint by removing any rust, dirt, or paint.

In order to choose the right filler metal, you must consider the composition of the base metal and the application for which it will be used. It’s important to ensure the filler metal and base metal have good compatibility to produce a strong joint.

By properly preparing and selecting the right materials, you can successfully braze weld steel.

Step-By-Step Guide To Braze Welding

Braze welding steel can be a challenging task, but with the right steps, you can achieve great results. First, ensure the surface is clean and pre-heated. This removes any impurities and leads to better adhesion of the filler metal. Next, apply the filler metal to the surface in a consistent manner.

Avoid over-applying, as this can cause weak spots in the weld. Finally, finish by cleaning the area with a post-welding process. This will give a smooth surface without any slag or debris. Remember to be patient and follow each step carefully for a quality braze weld.

Troubleshooting Common Issues

Braze welding steel can come with its share of challenges. Understanding the common issues that can arise and finding solutions quickly can avoid costly mistakes. One issue to watch out for is overheating the metal and creating brittle joints. Avoid this by using sufficient heat control and proper filler materials.

Another common problem is not properly cleaning the metal before welding. Make sure to remove any rust or other contaminants with a wire brush and acetone. Finally, be sure to secure all components tightly together before starting the weld. With these tips in mind, properly braze welding steel can be done with ease and efficiency.

Frequently Asked Questions Of How To Braze Weld Steel

What Type Of Steel Can Be Braze Welded?

Braze welding can be used on various types of steel, including low-carbon, high-carbon, and stainless steel. However, it’s important to choose the right brazing rod that matches the steel being welded.

What Equipment Is Needed For Braze Welding?

To braze weld steel, you need a propane torch, a brazing rod, flux, pliers, a wire brush, and safety gear such as gloves and goggles.

What Are The Advantages Of Braze Welding?

Braze welding is a low-heat method, which means the underlying material is less likely to become distorted. Additionally, it provides a strong, leak-free joint that can withstand harsh environments.

What Are Some Common Mistakes To Avoid When Braze Welding?

Some common mistakes include not cleaning the metal surface thoroughly, heating the metal too much, using the wrong filler metal, and not using enough flux. It’s important to follow instructions carefully and practice before tackling a major project.

Final Thoughts

Brazing-welding steel is not an easy task. It requires grit, precision, and knowledge of the basics of the process. However, it is a skill that can be mastered with time and practice. With the help of this guide, you now know how to braze-weld steel, and what it takes to do it right.

Whether you are a professional welder or a DIY enthusiast, following these steps will help you get the results you desire. Remember to always prioritize safety, properly prepare the surfaces, and choose the right materials for the job. Not only will this ensure the end result is seamless, but it will also increase the durability of your work.

So go ahead, try out these steps, and enjoy the satisfaction of a job well done.